TABLE OF CONTENTS

TABLE OF CONTENTS

Other Usefull Contents

You can see many success stories from our customers, and you may be one of them in the future

Unlock the Power of Mobile Commerce: Propel Your Business Forward

Read MoreDiscover how to harness mobile commerce to enhance your business growth. Learn strategies for optimizing the mobile shopping experience and increasing consumer engagement.

Read MoreDiscover the benefits of mobile commerce and how it can transform your business. Learn effective strategies for maximizing sales and customer engagement through mobile-optimized shopping experiences.

Read More

In a rapidly evolving global marketplace, the importance of streamlined operations cannot be overstated; in fact, according to a report by Grand View Research, the global warehouse management system market was valued at $2.62 billion in 2022 and is projected to grow at an impressive CAGR of 16.8% from 2023 to 2030. This statistic reflects a significant shift in how businesses are prioritizing efficiency and accuracy in their warehouse operations. Let me share the inspiring story of Lisa, a small eCommerce entrepreneur from Canada who was struggling with chaotic inventory management and costly order delays. After implementing Cmsmart's advanced Warehouse Management System, Lisa saw a remarkable 30% reduction in order delays, greatly enhancing customer satisfaction.

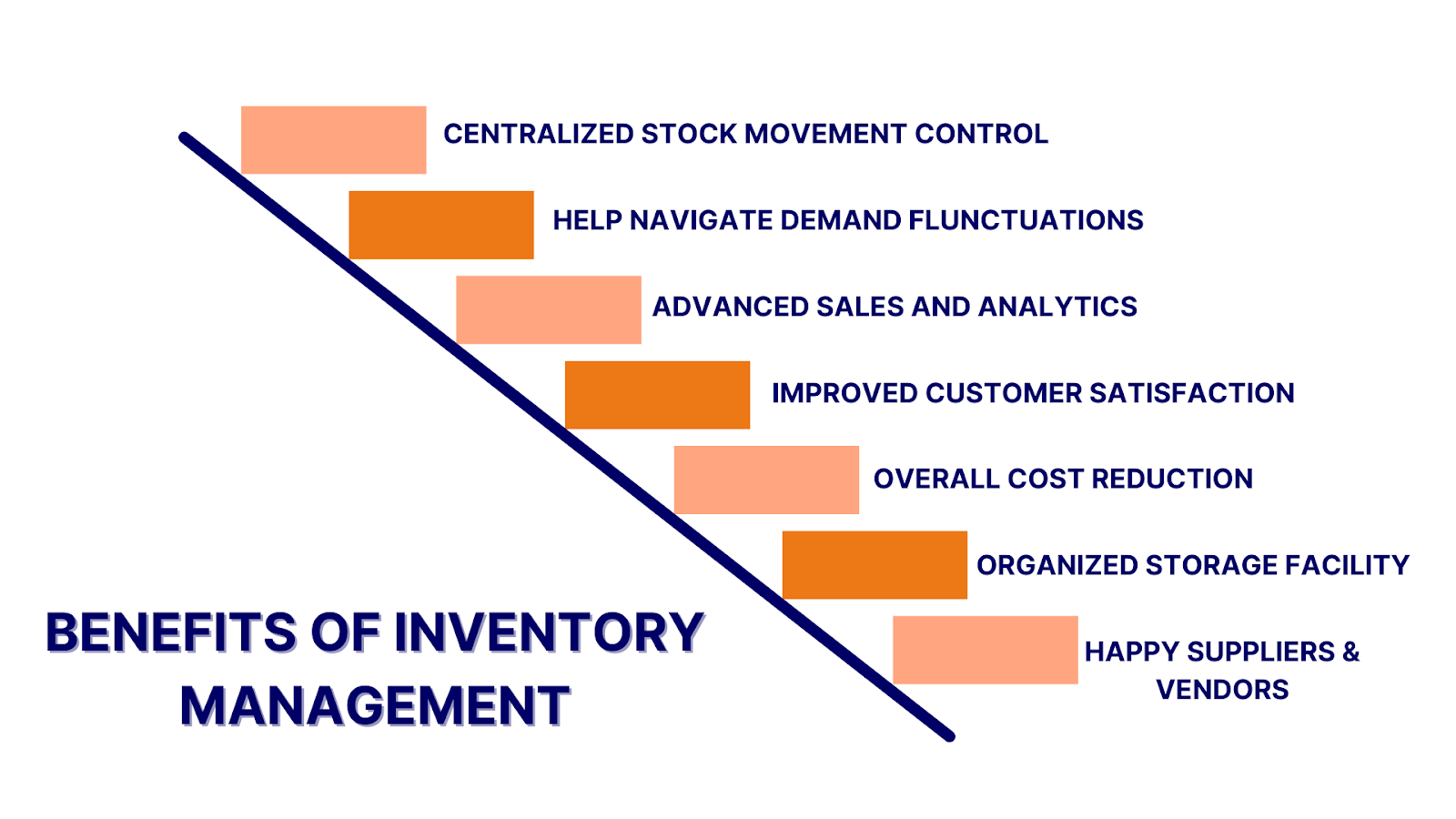

Many businesses like Lisa's grapple with the intricacies of managing a warehouse effectively. The absence of organized storage systems and real-time inventory tracking often leads to inefficiencies that stifle growth. That's where our expertise at Cmsmart can make a world of difference. By integrating a robust inventory management system along with smart operational solutions, companies can transform their warehouse operations into a flawless system that not only meets but exceeds customer expectations. Explore how our solutions can enhance your efficiency, or take a look at our guide on effective inventory management strategies. In this tutorial, we'll delve deeper into optimizing your business efficiency with a Warehouse Management System, equipping you with actionable strategies to streamline operations, reduce costs, and improve inventory management.

Imagine a Flawless Warehouse System

Struggling with chaotic warehouse operations? Youre not alone.Many businesses grapple with the need for organized storage systems, challenges in material handling, and difficulties in real-time inventory tracking. The absence of data-driven insights often results in inefficient order fulfillment processes that hinder growth.

Transform Your Warehouse Operations with Smart Solutions

To create a flawless warehouse system, consider implementing these actionable strategies:Data-Driven Decision Making

Establishing a system where insights shape your operations can significantly improve efficiency. Here are some tips:Streamlining Order Fulfillment Processes

Adopt best practices for order fulfillment to ensure efficiency:- Map out your fulfillment workflow.

- Implement technology solutions that facilitate faster processing.

- Train your team regularly on updated operational standards.

For more insights, explore our guides on Understanding Logistics Efficiency in Modern Warehouses and Leveraging Data Analytics for Warehouse Operations. In summary: A flawless warehouse system is not just a dream; its achievable through organized operations, data-driven strategies, and effective order fulfillment processes. Next, let’s dive into how to develop a robust Warehouse Management System to fully optimize your inventory management.Understanding Warehouse Management Systems

Need an organized storage system to streamline your operations? Youre not alone.Many businesses grapple with challenges like inefficient material handling, difficulty in real-time inventory tracking, and lack of data-driven insights, impacting order fulfillment processes.

Defining Warehouse Management System

A Warehouse Management System (WMS) is a software solution designed to oversee and control the flow of materials within a warehouse. It enhances the efficiency of logistics in eCommerce by managing inventory levels, streamlining order fulfillment, and optimizing storage solutions.Evolution and Importance of Warehouse Management System in Todays eCommerce World

As the eCommerce landscape continues to grow, understanding your warehouse operations becomes crucial. Market insights indicate that businesses investing in modern WMS experience a 25% reduction in inventory costs and a 30% improvement in order accuracy. This growth underscores the need for effective inventory management to stay competitive.Terminology: Comprehending Warehouse Operations

Understanding key terms related to your Inventory Management System can significantly enhance your logistics efficiency. Here are some essential concepts:Implementing Advanced Strategies

To take your WMS to the next level, consider these strategies:- Invest in real-time tracking solutions to enhance visibility

- Leverage data analytics to forecast demand trends

- Conduct regular inventory audits to reduce discrepancies

For further insights, explore our articles on How to develop a robust Warehouse Management System, Optimizing inventory management in eCommerce, and Understanding logistics efficiency in modern warehouses. In summary: A well-implemented Warehouse Management System is crucial for navigating the complexities of eCommerce logistics. Next, let’s discuss the role of real-time tracking in supply chain management to enhance efficiency even further.The Game Changer: Real-Time Inventory Tracking

Struggling with the chaos of inventory management? You’re not alone.Many businesses grapple with disorganized storage systems, inefficient order fulfillment processes, and the challenge of real-time inventory tracking, which can diminish operational effectiveness.

What is Real-Time Inventory Tracking?

Real-time inventory tracking is a method that keeps tabs on your stock levels continuously. Unlike traditional systems that require manual updates, this approach automates data collection and provides instant insights into what products are in stock, which are on order, and when they need replenishing.This system is critical for eCommerce operations, as it not only streamlines warehouse operations but also enhances customer satisfaction through timely order fulfillment.

Advantages of Utilizing Real-Time Inventory Tracking

Implementing real-time inventory tracking can transform your business operations. Here are some key benefits:Exploring Examples of Successful Real-Time Inventory Tracking Systems

Many companies have leveraged real-time inventory tracking to enhance their operations. For instance, major e-retailers like Amazon use sophisticated inventory management systems to manage their vast selection of products precisely. This ensures they can meet customer demand without delays.Pro Tips for Implementing Real-Time Inventory Tracking

To maximize the benefits of real-time tracking, consider the following strategies:- Choose a robust Inventory Management System that easily integrates with your existing platforms.

- Regularly audit your inventory to reconcile discrepancies.

- Utilize barcodes or RFID for accurate real-time data collection.

In summary: Real-time inventory tracking is critical for overcoming the common challenges in material handling and order fulfillment that many businesses face. Next, let’s delve into how to develop a robust Warehouse Management System that complements your inventory strategy.Inside the Warehouse Ecosystem

Struggling with the challenges of organized storage systems and efficient order fulfillment? You’re not alone.Many businesses encounter difficulties in material handling, real-time inventory tracking, and making data-driven decisions within their warehouse operations.

Understanding the Warehouse Ecosystem

The warehouse ecosystem is an intricate network of processes that manage inventory levels, streamline logistics in eCommerce, and optimize order fulfillment. A well-functioning warehouse is not just a storage space; it’s the backbone of an efficient supply chain.The Role of Inventory Management in the Warehouse Ecosystem

Inventory management plays a vital role in ensuring that businesses meet customer demand while keeping costs down.Impact of Modern Warehouse Solutions on Traditional Warehouse Operations

Modern warehouse solutions are transforming traditional operations by introducing advanced technology and automation.With features like:

- Automated picking and packing processes that increase efficiency.

- Integration with eCommerce platforms for seamless order fulfillment.

- Enhanced tracking systems that provide real-time visibility of inventory flows.

In summary: Understanding the warehouse ecosystem helps businesses address key challenges, optimize inventory management, and improve logistics efficiency. To delve deeper into essential topics such as how to develop a robust Warehouse Management System, optimizing inventory management in eCommerce, and understanding logistics efficiency in modern warehouses, stay tuned for the next section!Leveraging Technology for Warehouse Operations

Struggling with organized storage and real-time inventory challenges in your warehouse operations? Youre not alone.Many businesses face the difficulties of inefficient order fulfillment processes and a lack of data-driven insights for better decision making.

Importance of Modern Technology in Warehouse Operations

Modern technology is essential for streamlining warehouse operations and enhancing efficiency. Introducing advanced storage solutions not only improves inventory management but also minimizes the risk of errors and delays. Here are some highlights:Key Features of Material Handling Equipment

Investing in the right material handling equipment can solidify your warehouses efficiency. Look for the following key features:How to Choose a Warehouse Management System with Advanced Technology

Selecting the right Warehouse Management System (WMS) is crucial for maximizing your logistic capabilities. Here are actionable steps to help guide your decision:- Assess your specific logistical needs and challenges

- Evaluate system compatibility with your current technology stack

- Consider scalability for future growth

Additionally, look out for customer feedback on user-friendliness and ROI before making your final choice. In summary: Leveraging modern technology in warehouse operations leads to more organized storage systems, better material handling, and improved real-time inventory tracking—critical components for business success. Next, lets explore how to develop a robust Warehouse Management System for your needs. By continually optimizing your logistics to enhance your eCommerce operations, youll ensure sustained growth and efficiency across the board.Data-Driven Decisions and Digital Integration

Need for organized storage systems? You’re not alone.Many businesses struggle with challenges in material handling, difficulty in real-time inventory tracking, and a lack of data-driven insights for decision making, leading to inefficient order fulfillment processes.

Breaking Down the Concept of Data-Driven Decisions

Making informed choices in warehouse management ultimately revolves around data-driven decisions. This means utilizing data analytics to enhance operations, optimize inventory levels, and improve order fulfillment processes. Here are some actionable tips to get started:The Connection between Digital Integration and Warehouse Management

Digital integration involves unifying various processes to create a seamless flow of information between systems. Here are a few benefits and challenges to consider:Benefits and Challenges of Data-Driven Warehouse Management

Implementing data-driven strategies in warehouse management can yield significant advantages but also presents challenges. Consider the following:- Benefits:

- Better decision-making through enhanced data visibility.

- Ability to quickly adapt to market changes and customer demands.

- Increased efficiency through automation and optimization of warehouse operations.

- Challenges:

- Data quality and accuracy issues can hinder decision-making.

- Resistance to change within staff and existing processes.

- Continuous need for technology upgrades and employee training.

For further understanding, explore our guides on how to develop a robust Warehouse Management System, optimizing inventory management in ecommerce, understanding logistics efficiency in modern warehouses, and the role of real-time tracking in supply chain management. In summary: Embracing data-driven decisions and integrating digital solutions can transform your warehouse management practices. Next, let’s dive deeper into leveraging data analytics for more efficient warehouse operations.Best Practices for Implementing an Efficient Warehouse Management System

Need for organized storage systems? You’re not alone.Many businesses grapple with challenges in material handling, real-time inventory tracking, and inefficiencies in order fulfillment processes. An efficient Warehouse Management System (WMS) can significantly alleviate these pain points, boosting your operations and profitability.

Planning for Warehouse Management System Implementation

Implementing an effective WMS involves thoughtful planning. Here are essential steps to consider:Key Steps in Implementing an Efficient Warehouse Management System

A successful WMS implementation not only streamlines operations but also enhances inventory management. Follow these key steps:Case Studies on Successful Warehouse Management System Integrations

Learning from others can provide valuable insights. Explore these case studies of successful WMS integrations:- Case Study 1: An eCommerce giant reduced delivery times and improved customer satisfaction.

- Case Study 2: A logistics company optimized inventory levels and achieved cost savings.

In summary: Implementing a robust Warehouse Management System can turn your logistics challenges into operational efficiencies. For further exploration, check out our guides on how to develop a robust Warehouse Management System, optimizing inventory management in eCommerce, and the role of real-time tracking in supply chain management. Next, lets dive into how to leverage data analytics for warehouse operations for even greater insights.Future Trends in Warehouse Management Technology

Facing challenges in maintaining organized storage systems? Youre not alone.Many businesses struggle with issues like inefficient order fulfillment processes, real-time inventory tracking difficulties, and a lack of data-driven insights for making informed decisions.

Current Trends in Warehouse Management

To stay competitive, it’s crucial to understand the evolving landscape of warehouse operations. Some notable current trends include:Predicted Future Trends

Warehouse management is projected to continue evolving with these future trends:How to Future-Proof your Warehouse with Modern Management Solutions

To stay ahead, consider the following actionable tips:- Implement cloud-based systems for scalability and accessibility

- Adopt real-time tracking solutions for accurate inventory levels

- Regularly evaluate and update your logistics operations to meet eCommerce demands

For an in-depth look, check out our articles on How to develop a robust Warehouse Management System and Understanding logistics efficiency in modern warehouses. In summary: Embracing current and future trends in warehouse management technology helps businesses overcome existing challenges and thrive in a competitive landscape. Let’s dive next into exploring Optimizing inventory management in eCommerce to support your growth strategy!Frequently Asked Questions

Struggling with the complexities of managing your warehouse operations? You’re not alone.Many businesses face the pain points of disorganized storage systems, challenges in material handling, difficulties in real-time inventory tracking, and inefficient order fulfillment processes.

Understanding Warehouse Management Concepts

Frequently Asked Questions

What is a Warehouse Management System (WMS)?

Warehouse Management Systems are software solutions designed to enhance the operations of warehousing and inventory management. They facilitate a range of tasks from tracking inventory to optimizing order fulfillment.How does a WMS improve order fulfillment?

A Warehouse Management System streamlines the order fulfillment process through:- Real-time tracking of inventory levels

- Automation of picking and packing processes

- Delivery scheduling optimization

By improving these aspects, businesses can achieve faster turnaround times, leading to enhanced customer satisfaction.What are the key benefits of implementing a WMS?

Implementing a warehouse management system provides several advantages:What challenges do businesses face when using a WMS?

Common challenges can include:How can I optimize inventory management in eCommerce?

To optimize inventory management, consider these actionable tips:What is the role of data analytics in warehouse operations?

Data analytics is vital for:- Identifying patterns in inventory movement

- Improving demand forecasting

- Reducing stockouts and overstock situations

In summary: Addressing your warehouse management challenges with the right systems not only enhances your operational efficiency but also supports better decision-making in your business processes. Next, lets explore how to develop a robust Warehouse Management System that fits your unique needs. For more insights, check out the guides on optimizing inventory management in eCommerce, understanding logistics efficiency in modern warehouses, the role of real-time tracking in supply chain management, and leveraging data analytics for warehouse operations.Further Reading

Now that you’ve gained insight into streamlining your warehouse operations, it’s time to take action and implement these strategies for optimal efficiency. A robust Warehouse Management System not only enhances inventory accuracy but also reduces costs and improves overall operational workflows. Imagine a flawless warehouse system that transforms how you handle orders and satisfy your customers! If you’re ready to elevate your business to the next level, contact David, our CEO, directly at WhatsApp or email our Ecommerce Project Consultant at [email protected]. You can also request a quotation for a tailored solution that fits your specific needs. Let’s discuss how we can help you implement these efficient strategies and transform your warehouse operations.

David Nguyen

Founder & CEO, Cmsmart Ecommerce (a division of Netbase JSC)

With over 20 years of experience in business strategy and ecommerce technology, David Nguyen has empowered hundreds of online retailers around the world to scale smarter and faster. As the visionary behind Cmsmart, he has driven the development of personalization solutions and product-customization tools that deepen customer engagement and boost average order values. His commitment to creativity, practical strategy and results-driven outcomes has earned Cmsmart a reputation as a trusted partner for small, medium and enterprise-level ecommerce brands.

Contact Me via WhatsApp: https://wa.me/84937869689

Email: [email protected]

Let’s talk about how your ecommerce store can grow.

If you're ready to transform your store with tailored solutions that drive engagement and revenue, send me a message on WhatsApp or email today — and our team will connect with you right away.