TABLE OF CONTENTS

TABLE OF CONTENTS

Other Usefull Contents

You can see many success stories from our customers, and you may be one of them in the future

Unlock the Power of Mobile Commerce: Propel Your Business Forward

Read MoreDiscover how to harness mobile commerce to enhance your business growth. Learn strategies for optimizing the mobile shopping experience and increasing consumer engagement.

Read MoreDiscover the benefits of mobile commerce and how it can transform your business. Learn effective strategies for maximizing sales and customer engagement through mobile-optimized shopping experiences.

Read More

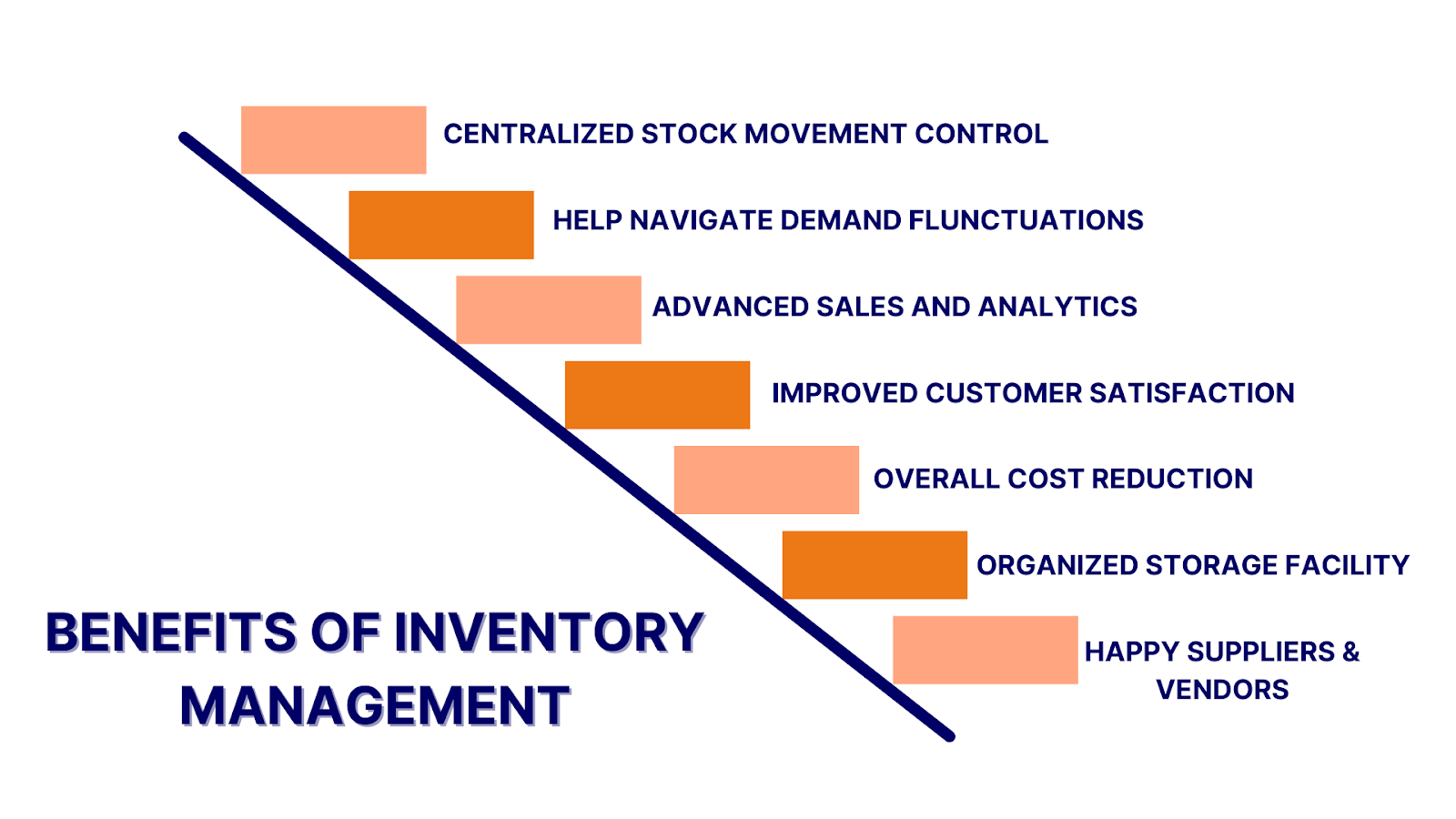

Inventory management can make or break your e-commerce business. Did you know that 43% of businesses believe their operational efficiency is directly impacted by inventory management issues? In today’s fast-paced marketplace, the stakes are higher than ever. Just ask John, a business owner from Australia, who operates a thriving online apparel store. Faced with inventory shortages and an overwhelmed warehouse, John struggled to keep pace with customer demands, leading to frustrated buyers and abandoned carts. By implementing Cmsmart's centralized inventory solutions, John transformed his operations, reducing stockouts by 45% and boosting customer satisfaction by 30% within just three months.

As the e-commerce landscape continues to evolve, understanding and optimizing your inventory management practices has become essential for sustainable growth. Many companies, like John's, experience challenges such as errors in stock levels and disorganized storage that lead to inefficiencies. These issues not only inflate costs but also hinder the customer experience, pushing businesses to abandon their competitive edge. To dive deeper into these pressing challenges and how to solve them, explore our resources on advanced inventory management and learn how you can revolutionize your business strategy. In this tutorial, we’ll outline actionable steps to help you unlock seamless inventory management and boost your e-commerce growth strategies for success.

Transforming the Stock Area

Imagine a world where you have absolute control over your inventory, ready to meet customer demands swiftly and efficiently.In todays rapidly changing marketplace, businesses often grapple with the challenges of poor stock management, particularly the lack of centralized control, which can lead to operational inefficiencies and dissatisfied customers.

Understanding the Inventory Dilemma

Many companies experience problems such as:Actionable Steps to Enhance Stock Management

To transform your stock area and overcome these challenges, consider implementing the following strategies:Success Story: Embracing Centralized Control

As one satisfied customer noted,Linking to Success

For more details on maintaining centralized control over stock movements, check out our guide on how to manage demand fluctuations. To explore ways to improve customer satisfaction through effective inventory strategies, visit this page. In summary: By adopting effective stock management strategies, businesses can enhance operational efficiency, mitigate costs, and ultimately improve customer satisfaction. Next, we will dive into advanced techniques for utilizing analytics to refine sales forecasts.Inventory Management Defined

Struggling with inventory issues that affect your business operations? You’re not alone.Many businesses grapple with challenges like lack of centralized control, making it hard to manage stock levels effectively, leading to errors, low customer satisfaction, and high costs.

Understanding Inventory Management and Its Importance

Effective inventory management is critical for maintaining optimal stock levels and ensuring timely fulfillment of customer orders. With the right inventory control strategies, you can improve purchasing decisions and operational efficiency while reducing issues like overstocking and stockouts.Breaking Down Key Terms: Stock Management, Supply Management, Inventory Control

Understanding key terms in inventory management can help clarify best practices: - Stock Management: The process of overseeing and controlling your company’s inventory, ensuring that the right amount is available at the right time. - Supply Management: The broader process that includes sourcing materials and ensuring that products are available for distribution. - Inventory Control: The strategies used to track and manage inventory levels efficiently, preventing excess or insufficient stock.Evolving Role of Inventory Management in Todays Business Landscape

In todays fast-paced market, effective inventory management is more important than ever. Consumer expectations for timely fulfillment are rising, making it essential for businesses to develop strategies to manage their inventory efficiently.By leveraging advanced analytics for sales forecasts, you can make informed stock decisions that enhance operational efficiency and improve customer satisfaction.

In summary: Mastering inventory management not only resolves common business pain points but also drives overall efficiency and profitability. Up next, we’ll explore how to maintain centralized control over stock movements, ensuring your inventory strategy is robust and responsive to market needs.Shifting Towards Centralized Control

Lack of centralized control leading to errors can cripple your inventory management efforts.Without a cohesive system for stock management, businesses often face challenges such as inefficient data use for forecasting and low customer satisfaction due to stock issues. This can result in overstocking, inadequate storage, and ultimately high costs.

What is Centralized Stock Management?

Centralized stock management refers to organizing and controlling inventory from a single location or system. It consolidates information about stock levels, movements, and purchasing decisions, enabling businesses to manage repurchase cycles efficiently.Benefits of Centralizing Your Inventory Control

Centralized inventory control provides various advantages to businesses, including:Making the Transition: How to Maintain Centralized Control Over Stock Movements

Transitioning to a centralized system requires strategic planning. Here are actionable tips to maintain centralized control over stock movements:- Adopt advanced analytics tools for accurate inventory forecasting

- Implement efficient storage solutions to organize stock facilities

- Regularly review and adjust inventory levels in response to demand fluctuations

- Utilize software that integrates seamlessly with existing systems for improved efficiency

For further insights, check out our articles on strategies to manage demand fluctuations, using advanced analytics for sales forecasts, and ways to improve customer satisfaction through inventory. In summary: Centralizing your inventory control not only minimizes errors but also optimizes your operational efficiency. In the next section, we will delve deeper into specific strategies that can further enhance your supply chain management.Demand Fluctuations and Their Impact

Struggling with managing your inventory effectively? You’re not alone.Many businesses grapple with the challenges posed by demand fluctuations that lead to overstocking, stockouts, and ultimately low customer satisfaction. The lack of centralized control can cause severe inefficiencies and heightened operational costs.

Defining Demand Fluctuations

Demand fluctuations refer to the constant changes in customer purchasing behavior, influenced by various factors such as seasonality, economic shifts, and market trends. Understanding these fluctuations is crucial for effective stock management and to ensure adequate inventory levels.Research indicates that over 70% of businesses experience stockouts due to improper demand forecasting. This problem underscores the importance of integrating robust inventory control systems that can adapt to varying demand scenarios.

How to Manage Demand Fluctuations in Inventory

To effectively tackle demand fluctuations, consider these actionable strategies:Essential Demand Forecasting Techniques

Implementing precise demand forecasting techniques enhances your ability to make informed purchasing decisions. Here are some essential approaches:By adopting these techniques, you can substantially improve your stock management and minimize issues related to overstocking or stockouts. If youre interested in maintaining centralized control over stock movements, consider exploring strategies for managing demand fluctuations and ways to improve customer satisfaction through effective inventory tactics.

In summary: By understanding and managing demand fluctuations, youll mitigate risks linked to poor inventory control and enhance customer satisfaction. Next, let’s delve into how to utilize advanced analytics for more accurate sales forecasts and further refine your inventory strategies.Harnessing the Power of Sales Analytics

Struggling with disorganized inventory and inaccurate sales forecasts? You’re not alone.Many businesses grapple with the challenges of insufficient centralized control leading to errors, inability to adapt to demand changes, and inefficient data use for forecasting. These issues often translate into low customer satisfaction due to stock problems, high costs from overstocking or inadequate storage, and disorganized facilities reducing operational efficiency.

Role of Advanced Analytics in Inventory Management

Utilizing advanced analytics can significantly enhance your inventory control and supply management practices. Here are actionable tips to improve your approach:How Analytics Tools Can Enhance Sales Forecasts

Analytics tools can transform how you make purchasing decisions and align your supply with consumer behavior. These technologies help forecast sales by analyzing past trends and current market conditions.Real-World Examples of Effective Analytics Utilization

Many businesses have successfully implemented analytics to overhaul their inventory management processes:- A leading apparel retailer reduced excess inventory by 25% by applying predictive analytics for better stock control.

- A major electronics vendor improved fulfillment rates by 15% after integrating advanced demand forecasting tools.

In summary: Harnessing the power of sales analytics not only streamlines your inventory management but also enhances overall customer satisfaction. For further insights, ensure you explore how to maintain centralized control over stock movements, strategies to effectively manage demand fluctuations, and ways to improve customer satisfaction through inventory. Ready to transform your inventory processes? Let’s dive deeper into understanding advanced analytics for sales forecasts in the next section.Linking Inventory Control and Customer Satisfaction

Struggling with stock management can severely impact your customer satisfaction levels.A lack of centralized control can lead to significant control errors, making it challenging to adapt to fluctuating demand, predict inventory needs, and maintain operational efficiency.

The Impact of Inventory on Customer Experience

Effective inventory control is essential to enhance customer satisfaction. When businesses manage their inventory well, they can:Enhancing Customer Satisfaction Through Smart Inventory Control

Here are some actionable tips to streamline your inventory processes while elevating customer satisfaction:Success Stories: Businesses Improving Customer Experience Through Inventory Management

Several businesses have successfully adopted inventory management solutions to enhance their customer experience. For instance, a well-known retailer reported that optimizing their stock kept customer complaints about stockouts to a minimum. They noted: By focusing on inventory management, businesses can leverage their supply chains to make informed purchasing decisions that positively impact customer engagement and loyalty. In summary: Mastering inventory control is vital for thriving in today’s competitive market. Explore how to maintain centralized control over stock movements, manage demand fluctuations, and utilize advanced analytics for a seamless customer experience. Next, we will dive into advanced strategies for reducing inventory-related costs.Strategizing for Cost Reduction

Struggling with high inventory costs and inefficient stock management? Youre not alone.Many businesses encounter significant challenges, such as lack of centralized control, difficulty in adapting to demand changes, and disorganized storage facilities, which can lead to errors, stockouts, and reduced customer satisfaction.

How Inventory Overstocking and Understocking Contribute to Costs

Inventory management is crucial for maintaining optimal inventory levels. Companies often face two extremes:Cost-Effective Inventory Strategies

To streamline operations and enhance operational efficiency, consider these cost-effective strategies:Methods for Reducing Inventory-Related Costs

By adopting effective methods, you can minimize inventory-related costs:- Limit excess stock by forecasting demand accurately.

- Use inventory turnover ratios to identify slow-moving items.

- Train staff on efficient stock management practices.

- Optimize storage facilities to enhance organization.

In summary: Effective inventory management is vital for reducing costs and improving customer experiences. To learn more about maintaining centralized control over stock movements and strategies to manage demand fluctuations, proceed to our next section.Optimizing Storage Organization for Efficiency

Is your storage organization causing delays and errors in your operations?Many businesses struggle with the consequences of disorganized storage, leading to inefficiencies that affect their bottom line and customer satisfaction.

Importance of Organized Storage Facilities

Organized storage facilities play a critical role in ensuring smooth operations and timely fulfillment. A well-maintained system not only enhances inventory control but also reduces costs associated with overstocking and stockouts.Alarm Signals: Disorganized Storage Facilities Reducing Efficiency

When storage areas are chaotic, the immediate effects are apparent. Here are some common signs that your storage is lacking organization:Top Tips for Effective Storage Facility Management

To elevate your storage organization, follow these actionable tips:- Implement a barcoding system to enhance tracking and stock management.

- Regularly audit your inventory levels to adjust stock decisions strategically.

- Create an organized layout that prioritizes high-turnover items for easy access.

For more detailed strategies, check our guide on maintaining centralized control over stock movements and tips for organizing a storage facility. In summary: Optimizing storage organization not only boosts efficiency but also aligns your operations with better customer satisfaction. Next, well discuss strategies to manage demand fluctuations effectively.Looking Ahead: Future Trends in Inventory Management

Lack of centralized control leading to errors? You’re in the right spot.Many businesses struggle with the challenge of maintaining accurate inventory management amidst fluctuating demand and operational inefficiencies. This often results in stockouts, overstocking, and ultimately, dissatisfied customers.

Emerging Technologies for Advanced Inventory Control

The future of inventory management is being reshaped by exciting technologies that enhance stock management and supply chain dynamics. Here are some key trends to watch out for:Predicting Future Inventory Management Trends

As technological advancements accelerate, companies must adapt their practices to stay ahead. Consider the following trends:Staying Ahead of the Game: Future-Proofing Your Inventory Management

Implementing strategies to future-proof your inventory processes will not only enhance operational efficiency but also elevate customer satisfaction. Here are actionable recommendations:- Invest in advanced software solutions that provide centralized control over stock movements

- Develop strategies to manage demand fluctuations effectively

- Utilize methods for reducing inventory-related costs and enhancing storage organization

In summary: As we look towards the future, adapting to these emerging trends and integrating advanced technologies can transform your inventory management approach. Next, we will delve into essential strategies for maintaining centralized control over stock movements to help you navigate the complexities of supply management effectively.Frequently Asked Questions

Lack of centralized control leading to errors? You’re not alone.Many businesses struggle with issues like stockouts, overstocking, and inefficient data use for forecasting, which ultimately leads to low customer satisfaction and higher operational costs.

Understanding Inventory Management Challenges

Inventory management, also known as stock management or supply management, is crucial for the success of any business. Here are some common pain points:

Actionable Tips for Effective Inventory Control

To enhance your inventory management, consider the following strategies:Enhancing Customer Satisfaction Through Inventory Management

Improving your inventory control can significantly boost customer satisfaction. Always keep your product availability aligned with customer expectations and ensure timely fulfillment. Strategies could include:

Further Reading

- How to Maintain Centralized Control Over Stock Movements

- Strategies to Manage Demand Fluctuations

- Using Advanced Analytics for Sales Forecasts

- Methods for Reducing Inventory-Related Costs

- Tips for Organizing a Storage Facility

In summary: Proper inventory management not only streamlines operations but also enhances customer satisfaction. For our next section, let’s dive deeper into effective techniques for managing inventory levels effectively.FAQ Section: Troubleshooting and Pro Tips

How can I centralize inventory management to reduce errors?

Utilizing an advanced inventory management system can eliminate discrepancies and improve accuracy across your channels.

What steps can I take to adapt to changing demand effectively?

Implement real-time inventory tracking to adjust stock levels based on current market trends and consumer behavior.

How do I make better use of data for forecasting?

Leverage analytics tools to analyze historical sales data, optimize inventory levels, and predict future demand.

What is the impact of stock issues on customer satisfaction?

Stockouts can lead to lost sales and customer dissatisfaction, prompting them to seek alternatives.

How can I reduce costs associated with overstocking?

Optimize your inventory turnover rate and utilize demand forecasting to maintain appropriate stock levels.

What strategies can improve the organization of storage facilities?

Implement a structured inventory system and visit storage regularly to ensure all items are easily accessible and well-cataloged.

Congratulations on taking the first step towards revolutionizing your inventory management! In this tutorial, we've shared actionable strategies to redefine your stock area, ensuring that you can swiftly turn challenges into opportunities for growth. By implementing centralized control systems and advanced analytics, you’ll not only enhance operational efficiency but also significantly boost customer satisfaction. Let’s discuss how we can help you implement these strategies effectively and elevate your e-commerce performance. Reach out to David, our CEO via WhatsApp for personalized insights or email our Ecommerce Project Consultant at [email protected]. For a tailored solution, don’t hesitate to request a quotation. Join me in transforming your store today!

David Nguyen

Founder & CEO, Cmsmart Ecommerce (a division of Netbase JSC)

With over 20 years of experience in business strategy and ecommerce technology, David Nguyen has empowered hundreds of online retailers around the world to scale smarter and faster. As the visionary behind Cmsmart, he has driven the development of personalization solutions and product-customization tools that deepen customer engagement and boost average order values. His commitment to creativity, practical strategy and results-driven outcomes has earned Cmsmart a reputation as a trusted partner for small, medium and enterprise-level ecommerce brands.

Contact Me via WhatsApp: https://wa.me/84937869689

Email: [email protected]

Let’s talk about how your ecommerce store can grow.

If you're ready to transform your store with tailored solutions that drive engagement and revenue, send me a message on WhatsApp or email today — and our team will connect with you right away.