TABLE OF CONTENTS

TABLE OF CONTENTS

Other Usefull Contents

You can see many success stories from our customers, and you may be one of them in the future

Unlock the Power of Mobile Commerce: Propel Your Business Forward

Read MoreDiscover how to harness mobile commerce to enhance your business growth. Learn strategies for optimizing the mobile shopping experience and increasing consumer engagement.

Read MoreDiscover the benefits of mobile commerce and how it can transform your business. Learn effective strategies for maximizing sales and customer engagement through mobile-optimized shopping experiences.

Read More

Are you struggling with excess stock or facing challenges in inventory forecasting? You're not alone. A staggering 52% of retailers experience issues with unsold or expired inventory, which leads to increased warehousing costs and dissatisfied customers. Take, for example, EcoWear, a sustainable clothing brand based in Canada. After struggling to manage their inventory effectively, they turned to Cmsmart’s advanced stock control solutions. Through improved forecasting and real-time data tracking, EcoWear transformed their inventory management, leading to a 30% reduction in excess stock within six months, thereby enhancing their overall customer satisfaction. This is just one of the success stories that underscores the critical role that efficient inventory management plays in e-commerce profitability.

In today's fast-paced market, the need for smart stock control solutions has never been more pressing. According to a report by Statista, the global market for inventory management solutions is projected to grow from $2.61 billion in 2020 to $6.16 billion by 2026, a clear indication that businesses are prioritizing efficient inventory practices. By tapping into technology for real-time insights and leveraging advanced tools, you can adopt strategies that not only streamline your operations but also significantly boost your profitability. Explore our guide on seamless inventory management here, and discover actionable tips to enhance your stock control processes. In this tutorial, we'll dive deep into the best practices and tools that can help you master your inventory management and position your e-commerce business for long-term success.

The Power of Efficient Inventory Management

Struggling with excess stock or inadequate market response? Youre not alone.Many businesses grapple with pain points such as unsold or expired inventory, high warehousing costs, and challenges in planning and forecasting. These issues can lead to inefficiencies that ultimately affect customer satisfaction.

The Power of Efficient Inventory Management

Picture the dramatic transformation in your business with improved forecasting capabilities, enhanced operational efficiency, and towering customer satisfaction levels, made possible by one change – refined inventory management. By focusing on stock control and supply chain management, you can achieve a remarkable shift in your operational landscape. Here are actionable tips for better inventory control:Understanding Benefits Through Effective Inventory Management Strategies

With effective strategies, you not only reduce warehousing costs but also improve your order fulfillment processes, leading to increased customer satisfaction. For more insights, explore our guides on Effective Inventory Management Strategies, Improving Order Fulfillment Through Inventory Control, and Reducing Warehousing Costs with Better Inventory Management. Expert Opinion:Summary

Efficient inventory management is vital in addressing critical business pain points. By implementing the strategies discussed, you can enjoy improved forecasting, operational efficiency, and customer satisfaction. Next, let’s delve into understanding the risks of poor inventory handling and how to mitigate them effectively.Interpreting Inventory Management

Lack of market responsiveness and high warehousing costs can be crippling for any business.Many companies struggle with unsold or expired stock, leading to inefficiencies that diminish customer satisfaction and hinder operational efficiency.

Definition of Inventory Management

Inventory management is the process of overseeing and controlling stock levels to ensure that the right amount of products is available at the right time. This involves both stock control and inventory control, which work together to balance supply and demand across the supply chain.

The Relationship between Stock Control and Inventory Control

Stock control focuses on maintaining optimal stock levels, while inventory control encompasses broader practices, including tracking, ordering, and managing products throughout the supply chain. Together, they form the backbone of effective inventory management, ensuring that businesses can respond rapidly to market demands.

The Significance of Inventory Control in Supply Chain Management

Effective inventory control plays a vital role in supply chain management, helping businesses to:

Integrating strong inventory control practices not only addresses common pain points but also fosters greater transparency and collaboration within your supply chain. Happy customers are often the result of an agile and responsive inventory management system.

For deeper dives into effective strategies, check out our guides on Effective Inventory Management Strategies, Improving Order Fulfillment Through Inventory Control, Reducing Warehousing Costs with Better Inventory Management, and Understanding the Risks of Poor Inventory Handling.

In summary: Properly interpreting and applying inventory management principles can transform your business operations, prepare you for market changes, and ultimately lead to improved customer satisfaction. Next, let’s explore effective strategies for enhancing inventory practices even further.Inventory Management and Your Business Health

Lack of market responsiveness, unsold or expired stock, and high warehousing costs can significantly impact your business health.In todays fast-paced e-commerce landscape, effective inventory management is critical for maintaining customer satisfaction and operational efficiency.

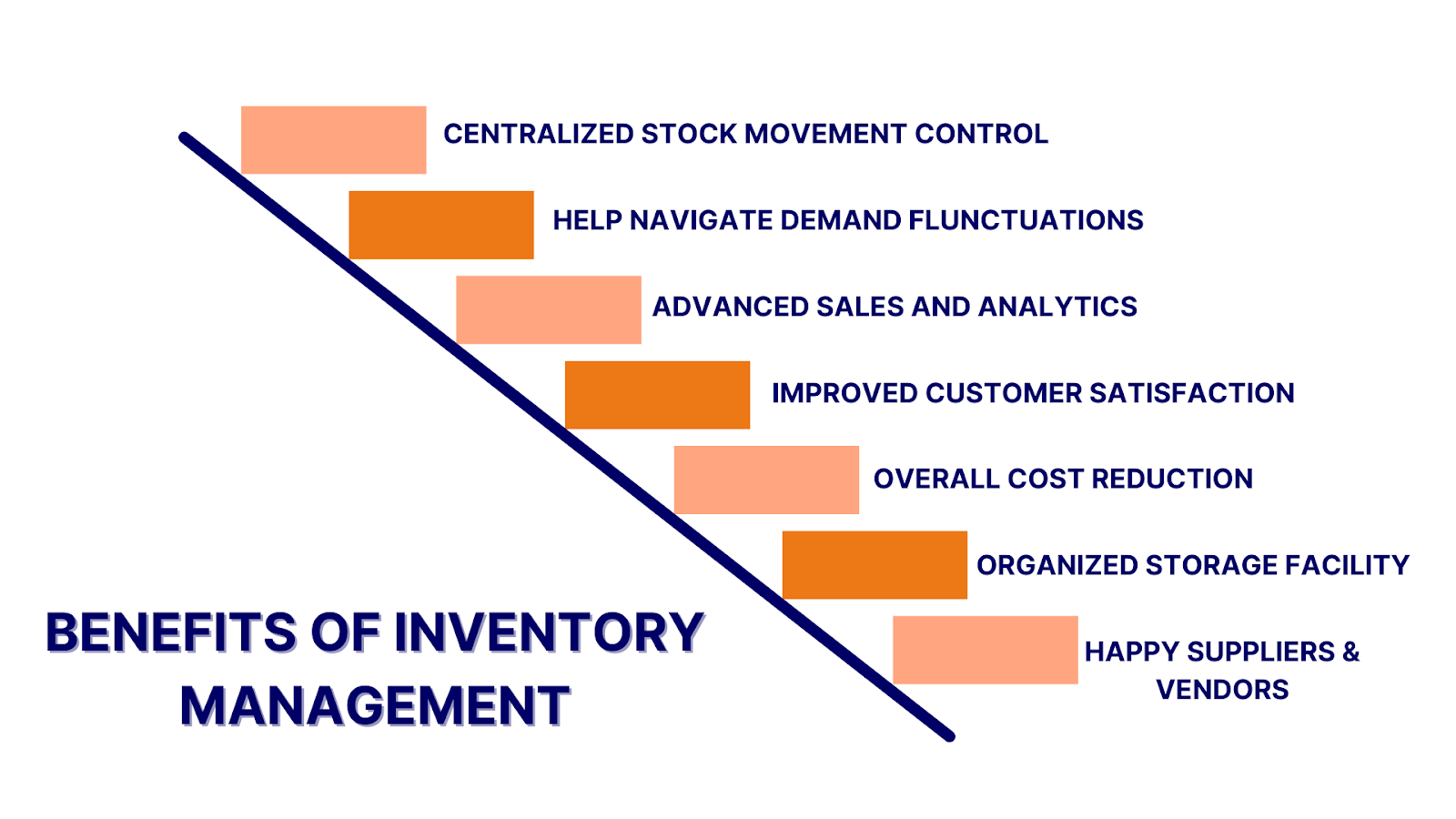

The Benefits of Efficient Inventory Management

Proper stock control not only helps in meeting market demands but also enhances your forecasting capabilities. Here are some key benefits:

Risks Associated with Poor Inventory Management

On the flip side, failure to manage your inventory can lead to significant challenges:

Real-life Illustrations of Inventory Management Wins and Losses

Learning from others can provide valuable insights:

Conclusion

Efficient inventory management is crucial for business health, enabling you to respond swiftly to market demands while minimizing risks associated with poor practices. For more in-depth strategies, explore our guides on Effective Inventory Management Strategies, Improving Order Fulfillment Through Inventory Control, Reducing Warehousing Costs with Better Inventory Management, and Understanding the Risks of Poor Inventory Handling.

In summary: Leveraging the benefits of sound inventory practices not only protects your bottom line but also enhances your overall brand reputation—next, let’s dive into effective strategies for managing your stock efficiently.The Mechanics of Inventory Management: Key Elements and Processes

Lack of effective inventory management can lead to significant challenges such as market unresponsiveness, unsold or expired stock, and soaring warehousing costs.Many businesses grapple with properly managing their stock levels, ultimately harming operational efficiency and customer satisfaction.

Understanding Stock Levels

Effective stock control is crucial for any business aiming to meet market demands without incurring excessive costs. Here are some actionable tips to manage your stock levels effectively:The Role of Forecasting Capabilities

Accurate forecasting enhances your ability to anticipate market trends, helping businesses make informed decisions regarding inventory planning. Here are key points to consider:How Inventory Planning Impacts a Business

Well-executed inventory planning can significantly improve customer satisfaction by ensuring that products are available when customers need them. Consider the following:- Maintain a balanced inventory to prevent both shortages and overstock situations.

- Invest in employee training on inventory management best practices.

- Utilize data-driven insights to refine your inventory strategies further.

In summary: By understanding key elements such as stock levels, forecasting capabilities, and the impact of inventory planning, you can enhance your inventory strategies. For deeper insights, check out our articles on Effective Inventory Management Strategies, Improving Order Fulfillment Through Inventory Control, Reducing Warehousing Costs with Better Inventory Management, and Understanding the Risks of Poor Inventory Handling as we transition to discussing advanced inventory management processes in the next section.Inventory Management and Market Responsiveness

Is your inventory management holding you back from responding swiftly to market demands? Youre not alone.Many businesses struggle to meet customer expectations due to unsold stock, expired products, and high warehousing costs.

Inventory Management’s Role in Responding to Market Demands

Effective inventory management is crucial in supply chain management. Proper stock control enables businesses to align their inventory levels with market demands, ensuring that products are available when customers want them. Here are a few actionable tips to enhance your responsiveness:The Adverse Effect of Unsold or Expired Stock

Keeping excess unsold or expired stock can lead to significant financial losses and wastage. To mitigate these issues, consider the following strategies:Strategies for Adapting Inventory Management to Market Changes

Every market shift offers an opportunity to refine your inventory control processes. Here are proven strategies to adapt:- Invest in demand forecasting tools that leverage machine learning for more accurate predictions.

- Enhance collaboration with suppliers to ensure quicker response times for changing market demands.

- Adopt flexible inventory models that allow rapid adaptation to market fluctuations.

In summary: Developing strategic inventory management practices empowers businesses to respond effectively to market demands, minimizes the risks of unsold stock, and optimizes warehousing costs. For more insights, visit our sections on Effective Inventory Management Strategies, Improving Order Fulfillment Through Inventory Control, Reducing Warehousing Costs with Better Inventory Management, and Understanding the Risks of Poor Inventory Handling. Next, lets explore how these strategies translate into better customer satisfaction and operational efficiency.Impacting the Bottom Line: Order Fulfillment and Warehousing Cost Savings

Struggling to manage your operational costs effectively? You’re not alone.Many businesses face challenges like high warehousing costs, unsold stock, and difficulties in forecasting market demands, leading to inefficiencies that can hurt customer satisfaction.

The Influence of Inventory Control on Order Fulfillment

Effective inventory control is crucial for optimizing order fulfillment and minimizing costs. When businesses know their stock levels well, they can respond to market demands quickly, avoiding excess inventory and expired stock.

Reducing Warehousing Costs Through Effective Inventory Management Strategies

Reducing warehousing costs involves more than just cutting expenses; it’s about strategic management. Here are some techniques that can lead to significant savings:

Illustrating Cost-saving Techniques in Inventory Management

Implementing innovative strategies in inventory management can yield impressive cost savings. Consider these actionable methods:

- Leverage data analytics to identify purchasing trends and optimize order quantities.

- Train staff on inventory best practices to improve handling and minimize shrinkage.

- Consider drop shipping arrangements to reduce warehousing altogether.

In summary: Mastering order fulfillment and controlling warehousing costs through effective inventory control strategies is vital for any business aiming for operational efficiency and increased profitability. Next, let’s dive into the Effective Inventory Management Strategies and explore how they can revolutionize your inventory handling processes.Enhancing Customer Satisfaction Through Inventory Management

Struggling with high warehousing costs and poor customer satisfaction? You’re not alone.Many businesses face significant challenges like lack of market responsiveness and inefficiencies in inventory that lead to unsold or expired stock.

The Connection between Customer Satisfaction and Inventory Management

Effective inventory management plays a pivotal role in enhancing customer satisfaction. When businesses accurately forecast stock needs and maintain optimal stock levels, they can better meet market demands, leading to happier customers. Here are some ways inventory control directly influences customer satisfaction:Identifying Inefficiencies Leading to Poor Customer Satisfaction

To enhance customer satisfaction, it’s crucial to identify areas where inefficiencies arise. Common issues include:Effective Techniques for Boosting Customer Satisfaction Through Inventory Control

Here are actionable techniques to enhance inventory management and subsequently boost customer satisfaction:By employing these techniques, businesses can improve operational efficiency, reduce costs, and ultimately elevate customer satisfaction. As one customer shared:

In summary: Enhancing customer satisfaction through effective inventory management is not just beneficial; its essential. As we move forward, dive deeper into Effective Inventory Management Strategies, Improving Order Fulfillment Through Inventory Control, Reducing Warehousing Costs with Better Inventory Management, and Understanding the Risks of Poor Inventory Handling. Embrace these strategies for a seamless customer experience and manage your inventory effectively!Forecasting and Planning: Mitigating Inventory Management Challenges

Struggling with inventory management challenges? You’re not alone.Many businesses face the critical issues of lack of market responsiveness, unsold or expired stock, and high warehousing costs, leading to inefficiencies and poor customer satisfaction.

The Challenges of Inventory Forecasting and Planning

Effective inventory forecasting and planning are essential for ensuring that stock levels align with market demands. However, businesses often encounter hurdles such as:

Strategies for Better Inventory Forecasting

To enhance forecasting capabilities, businesses can implement the following strategies:

Ways to Improve Inventory Planning and Control

Improving inventory planning and control is vital for operational efficiency. Here are actionable tips:

- Set minimum and maximum stock levels for all products;

- Implement ABC analysis to prioritize inventory management tasks;

- Adopt just-in-time inventory practices to minimize excess stock;

- Train staff on best practices for inventory control and management.

In summary: By overcoming the challenges of inventory forecasting and planning, businesses can enhance their stock control, align inventory levels with market demands, and ultimately improve customer satisfaction. For a deeper dive, explore our resources on Effective Inventory Management Strategies, Improving Order Fulfillment Through Inventory Control, Reducing Warehousing Costs with Better Inventory Management, and Understanding the Risks of Poor Inventory Handling. Next, let’s explore advanced techniques for optimizing your inventory processes.Frequently Asked Questions

Struggling to manage your inventory effectively? You’re not alone.Many businesses grapple with challenges like lack of market responsiveness, unsold or expired stock, and high warehousing costs, all of which lead to inefficiencies and poor customer satisfaction.

Understanding Common Inventory Management Misconceptions

Addressing Market-Driven Inventory Management Queries

When it comes to inventory management, there are several common queries that can create confusion among business owners: - How can I avoid unsold stock? - Implement better demand forecasting through historical sales data analysis. - What are the benefits of effective stock control? - Enhanced operational efficiency - Improved customer satisfaction - Reduction in warehousing costs A real-world example comes from Anne, a retail manager who implemented new inventory tracking software. She shared:Actionable Strategies for Effective Inventory Management

To tackle the challenges of inventory management head-on, consider these actionable strategies:Further Reading

Congratulations on taking the first steps toward mastering your inventory management! By implementing the strategies outlined in this tutorial, you're well on your way to not only reducing excess stock and warehousing costs but also boosting overall efficiency and customer satisfaction. Imagine the power of real-time data and optimized forecasting at your fingertips—transforming your operations and profitability. Ready to elevate your e-commerce store? Let’s discuss how we can help you implement these advanced stock control solutions tailored to your unique needs. Reach out to David, our CEO via WhatsApp, or email our Ecommerce Project Consultant at [email protected]. You can also request a quotation today. Join us in shaping your path to e-commerce success!

David Nguyen

Founder & CEO, Cmsmart Ecommerce (a division of Netbase JSC)

With over 20 years of experience in business strategy and ecommerce technology, David Nguyen has empowered hundreds of online retailers around the world to scale smarter and faster. As the visionary behind Cmsmart, he has driven the development of personalization solutions and product-customization tools that deepen customer engagement and boost average order values. His commitment to creativity, practical strategy and results-driven outcomes has earned Cmsmart a reputation as a trusted partner for small, medium and enterprise-level ecommerce brands.

Contact Me via WhatsApp: https://wa.me/84937869689

Email: [email protected]

Let’s talk about how your ecommerce store can grow.

If you're ready to transform your store with tailored solutions that drive engagement and revenue, send me a message on WhatsApp or email today — and our team will connect with you right away.