TABLE OF CONTENTS

TABLE OF CONTENTS

Other Usefull Contents

You can see many success stories from our customers, and you may be one of them in the future

Unlock the Power of Mobile Commerce: Propel Your Business Forward

Read MoreDiscover how to harness mobile commerce to enhance your business growth. Learn strategies for optimizing the mobile shopping experience and increasing consumer engagement.

Read MoreDiscover the benefits of mobile commerce and how it can transform your business. Learn effective strategies for maximizing sales and customer engagement through mobile-optimized shopping experiences.

Read More

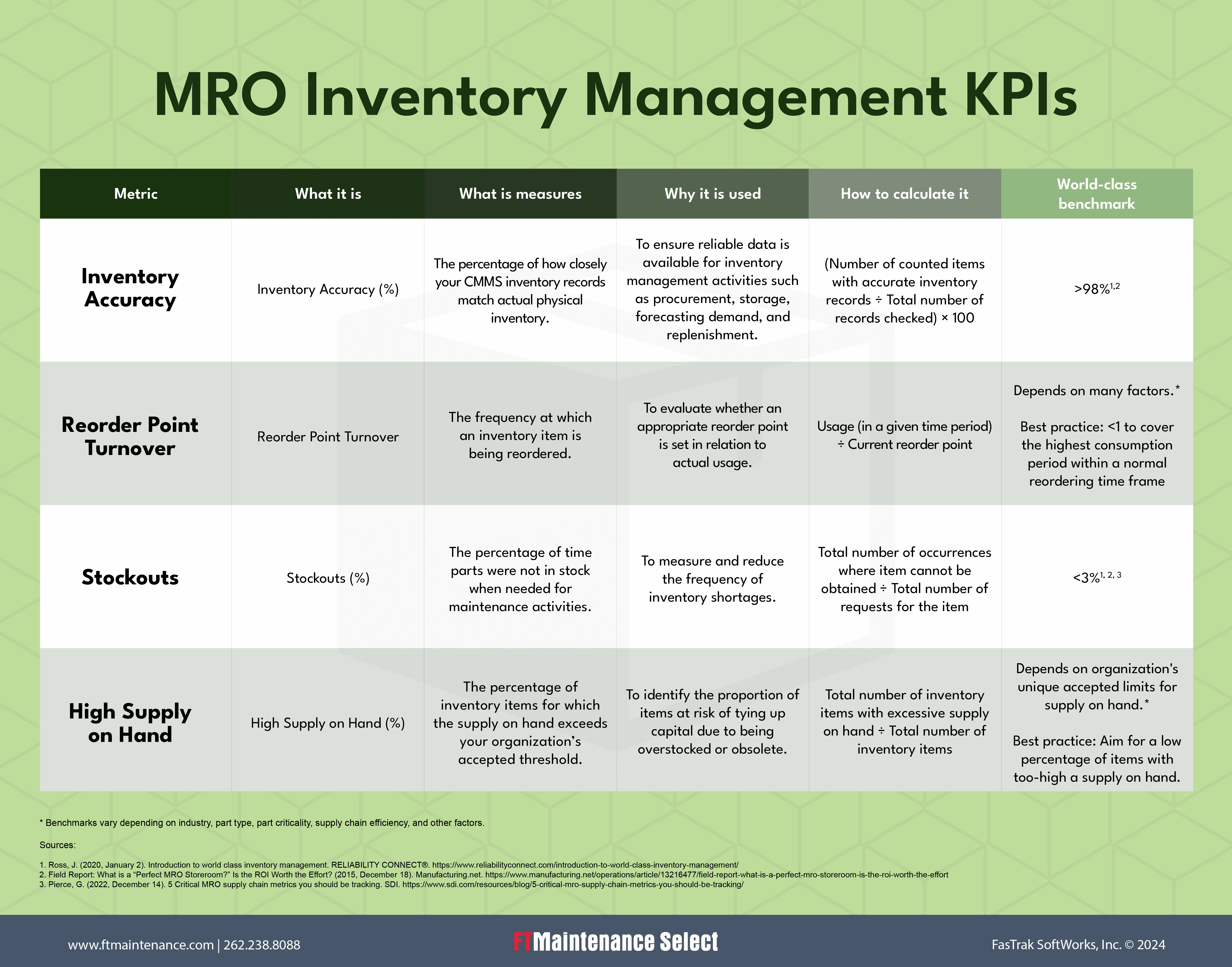

In today's fast-paced eCommerce landscape, effective inventory management isn't just a luxury—it's a necessity. Did you know that companies with optimized inventory management can reduce operational costs by 15-35% and boost customer satisfaction by up to 20%? This is particularly crucial in sectors like clinical laboratories, where every second of downtime translates into significant financial loss. For instance, our recent client, LabTech Solutions, based in Canada, faced substantial challenges due to poor inventory visibility and excessive human error in stock management, leading to operational disruptions and waste that cost them dearly.

After partnering with Cmsmart, LabTech implemented our advanced inventory management solutions, allowing them to streamline supply chain operations and automate replenishment processes. The result? A remarkable reduction in wastage, fewer errors, and an overall elevation in efficiency. This transformation not only saved them costs but also improved their service delivery. By focusing on inventory management optimization, we not only alleviate common pain points faced by many businesses but also drive profitability and growth. Explore effective inventory management strategies and discover how to elevate your business operations.

In this tutorial, we will discuss actionable tips and advanced solutions that can help you unlock inventory management optimization and elevate your business efficiency.

Why Inventory Management Optimization Matters

What if you could minimize wastage, eliminate errors, and boost efficiency in your clinical lab just by optimizing your inventory management?Many clinical laboratories grapple with the challenges of ineffective inventory control, leading to significant operational disruptions and financial losses.

Understanding the Importance of Inventory Management Optimization

Challenges such as lack of visibility into supply chain activities, excessive human intervention leading to errors, inefficient resource allocation, delayed replenishment of necessary reagents, and difficulty in tracking storage and shipment statuses can be detrimental to lab efficiency.Actionable Tips for Effective Inventory Management

To enhance inventory control processes, consider the following strategies:Building Efficiency Through Technology

Understanding the role of technology in stock management improvement is essential. From automated reorder alerts to mobile solutions for real-time monitoring, technology can dramatically enhance lab operations. For more detailed strategies, explore how to optimize your clinical labs inventory management, or learn about the benefits of ERP systems in inventory control. In summary: By addressing key pain points and implementing targeted strategies, labs can significantly improve their inventory management practices, leading to enhanced efficiency and reduced costs. Next, let’s dive into how to streamline inventory with lab automation for even greater gains.Understanding Inventory Management Optimization

Lack of visibility into supply chain activities can lead to costly errors and inefficiencies in clinical labs.Excessive human intervention often results in mistakes, while inefficient resource allocation and delayed replenishment of necessary reagents can seriously impact lab operations.

The Concept of Inventory Management Optimization

Inventory Management Optimization, or Inventory Control Enhancement, focuses on streamlining processes within your clinical lab to ensure that necessary supplies are always available while minimizing waste. This involves utilizing advanced technology and strategic planning to improve stock management.Importance of Inventory Control Enhancement in Clinical Labs

An efficient inventory system is crucial in clinical labs, where timely access to supplies directly impacts patient care. By enhancing your inventory control, you can:Various Elements of Stock Management Improvement

A holistic approach to stock management improvement includes several key elements:- Demand Forecasting: Use historical data to predict future needs, enabling better planning.

- Technology Implementation: Implement mobile technology to enhance tracking and management capabilities.

- Training Staff: Ensure your staff is familiar with the latest inventory management tools and techniques.

- Regular Audits: Conduct routine assessments of your stock levels and processes to identify areas for improvement.

In summary, effective inventory management optimization is paramount for clinical labs to thrive. Transitioning to this model will not only improve your operations but also lead to better patient care outcomes. Next, we will dive into how to Optimize your clinical labs inventory management effectively.Exploring the Power of Clinical Lab ERP Applications

Lack of visibility and efficiency in clinical labs can lead to critical delays and increased costs.Many laboratories struggle with excessive human intervention, resulting in errors and inefficient resource allocation. This can lead to delayed replenishment of necessary reagents and difficulty tracking supplies throughout the shipment process.

Definition and Importance of Clinical Lab ERP Applications

Clinical Lab ERP (Enterprise Resource Planning) applications are integrated systems that streamline operations, improve supply chain visibility, and enhance inventory control. By leveraging ERP technologies, clinical labs can automate processes to minimize human errors, optimize resource allocation, and ensure timely availability of critical supplies.Benefits of Implementing ERP Systems for Inventory Control

The implementation of ERP systems within clinical laboratories offers numerous advantages:Successful Cases of ERP Application in Clinical Laboratory

Several clinical labs have successfully adopted ERP systems to transform their operations:- XYZ Clinical Lab enhanced its inventory tracking, achieving a 70% reduction in stock discrepancies.

- ABC Lab implemented an automated replenishment system, ensuring timely delivery of reagents and supplies.

For more details, explore how to optimize your clinical labs inventory management or learn about the benefits of ERP systems in inventory control. In summary: Embracing ERP solutions can significantly enhance operational efficiency in clinical laboratories. In our next section, we will dive deeper into how to streamline inventory management with lab automation for seamless operations.The Role of Automation and Analytics in Lab Inventory Optimization

Lack of visibility into supply chain activities can significantly hinder a labs operational efficiency.Many clinical laboratories grapple with issues such as excessive human intervention leading to errors, inefficient resource allocation resulting in waste, and delayed replenishment of essential reagents. These challenges emphasize the necessity for automation and analytics in lab inventory optimization.

The Influence of Clinical Lab Automation on Inventory Management

Automation plays a pivotal role in enhancing inventory control, allowing labs to streamline their operations and improve stock management. By implementing automated systems, laboratories can achieve:How Real-Time Analytics Shape Inventory Decisions

Real-time analytics transform how labs approach inventory management by providing actionable insights that enhance decision-making. Utilizing real-time data analysis can result in:Benefits and Challenges in Leveraging Lab Analytics

While the advantages of leveraging lab analytics are significant, there are challenges to navigate. These include:- Initial investment in analytics technology and training

- Integration hurdles with existing lab systems

- Data overload leading to analysis paralysis if not managed properly

In summary, automating lab operations and leveraging real-time analytics can significantly enhance inventory management, mitigate risks, and optimize resource allocation. By overcoming challenges and steadily integrating these technologies, labs can ensure their operations remain efficient and effective. Next, let’s explore how to optimize your clinical labs inventory management through effective ERP systems.Unwrapping the Concept of Clinical Lab Demand Planning

Struggling with visibility into your clinical labs supply chain? Youre not alone.Many laboratories grapple with challenges such as inefficient resource allocation, excessive human intervention leading to errors, and delayed replenishment of essential reagents.

Need for Effective Demand Planning Strategies in Laboratories

Implementing robust demand planning strategies is crucial for laboratory operations. Here are some key points to focus on:The Impact of Demand Forecasting on Resource Allocation

Efficient demand forecasting can significantly impact resource allocation. Take these steps to optimize your labs resource management:Exploring Examples of Clinical Lab Demand Planning Accuracy

By examining successful demand planning strategies, labs can learn valuable lessons. For instance:- Implementing automated systems that reduce human errors and enhance inventory accuracy.

- Collaborating with suppliers to predict demand fluctuations and maintain optimal stock levels.

In summary: By leveraging demand forecasting and enhancing resource allocation, clinical labs can minimize costs and improve operational efficiency. Next, well dive into how to optimize your clinical labs inventory management. For further reading, consider exploring benefits of ERP systems in inventory control and how to streamline inventory with lab automation.Leveraging Mobile Tech for Inventory Management

Is your lab suffering from a lack of visibility into supply chain activities and inefficient resource allocation?Many labs struggle with excessive human intervention leading to errors, delayed replenishment of necessary reagents, and difficulty in tracking storage and shipment statuses.

Understanding the Impact of Mobile Technology in Lab Operations

Implementing mobile technology in laboratories can significantly enhance inventory control and stock management by providing real-time analytics and increased supply chain visibility. Mobile apps and devices enable lab staff to monitor inventory statuses on-the-go, thereby reducing lead times and improving replenishment timelines.Steps in Implementing Mobile Technology in Labs

Transitioning to mobile tech requires a strategic approach. Here are the steps you should consider:Benefits and Drawbacks of Lab Mobile Tech

Mobile technology offers diverse advantages but comes with some challenges. Benefits include:- Improved supply chain visibility

- Enhanced data accuracy and reduced manual errors

- Streamlined inventory management and replenishment processes

- Increased flexibility for lab personnel

Drawbacks may include:- Initial costs of technology setup

- Potential resistance to change among staff

- Dependence on internet connectivity

In summary: Leveraging mobile technology is critical for improved inventory management in labs. As you consider implementing these solutions, keep in mind the benefits they can yield, as well as the challenges that may arise. Next, let’s delve into how to optimize your clinical labs inventory management through advanced ERP systems, enhance your resource allocation, and utilize real-time analytics for informed inventory decisions.Solving Common Inventory Management Challenges

Struggling with common inventory management challenges? Youre not alone.Many businesses grapple with issues like a lack of visibility into supply chain activities, inefficient resource allocation, and delays in replenishment of necessary resources.

Overcoming the Issue of Lack of Visibility into Supply Chain Activities

Clear visibility into your inventory flow is crucial for effective inventory management. Lack of this visibility can lead to errors and delays that impact your operations.Ensuring Efficient Resource Allocation and Waste Minimization

Inefficient resource allocation can lead to unnecessary waste, like overstocking or stockouts. To combat this, consider the following strategies:Addressing Replenishment Timelines and Tracking Shipment Statuses

Delayed replenishment of necessary items can disrupt your operations. Implementing systematic tracking can help.- Utilize automated inventory notifications for low stock alerts.

- Implement shipment tracking software to stay updated on status changes.

- Coordinate closely with suppliers to establish effective replenishment schedules.

In summary: Tackling these common inventory management challenges requires a mix of technology implementation, process optimization, and strategic planning. Next, let’s delve into how you can optimize your clinical labs inventory management and explore the benefits of effective ERP systems in inventory control.Towards Better Resource Planning and Inventory Control

Lack of visibility into supply chain activities can lead to excessive human intervention, resulting in errors and inefficient resource allocation.This not only hampers productivity but also causes unnecessary waste and delayed replenishment of necessary lab reagents.

Exploring the Need for Technology Implementation in Labs

The integration of technology in resource planning and inventory control is crucial for modern laboratories. Implementing systems such as Enterprise Resource Planning (ERP) can dramatically enhance inventory management by ensuring real-time supply chain visibility.Understanding the Concept of Supply Chain Visibility

Supply chain visibility enables labs to monitor their inventory levels in real-time, leading to better replenishment timelines and less waste. By embracing technology, labs can significantly improve their stock management. Consider these steps:How to Maximize Efficiency with Inventory Management Optimization

Optimizing your inventory management can lead to significant improvements in overall lab operations. Here are key strategies:- Streamline your ordering processes to ensure timely delivery of essential reagents.

- Invest in automation tools to minimize manual handling and errors.

- Track usage patterns to forecast future needs better.

In summary: Implementing advanced technological solutions not only enhances resource planning and inventory control but also elevates overall operational efficiency. Next, we will explore how to optimize your clinical labs inventory management effectively, ensuring your lab runs seamlessly and meets the demands of modern-day operations. For further insights, check out our resources on Benefits of ERP systems in inventory control and Streamline inventory with lab automation.Frequently Asked Questions

Lack of visibility into supply chain activities can seriously undermine your labs efficiency.Many laboratories struggle with excessive human intervention leading to errors, inefficient resource allocation, and delays in replenishment of necessary reagents.

Frequently Asked Questions about Inventory Management Optimization

How can I improve visibility in my inventory management system?

What are the benefits of real-time analytics in inventory management?

How can I streamline my inventory replenishment timelines?

What technology can help with inventory tracking?

How does demand forecasting enhance inventory management?

Enhanced demand forecasting allows laboratories to accurately predict inventory needs, preventing waste and ensuring availability.

Where can I find more information on optimizing inventory management?

For further insights, explore our articles on Optimize your clinical labs inventory management, Benefits of ERP systems in inventory control, and Utilize real-time analytics for inventory decisions.FAQ Section: Troubleshooting and Pro Tips

How can I optimize my inventory management process?

Utilize real-time data tracking and strategic planning for efficiency.

What can I do about poor visibility in my supply chain activities?

Implement advanced inventory management solutions to enhance transparency.

How can I reduce human errors in my inventory management?

Automate processes with inventory management systems to minimize manual input.

What strategies help in efficient resource allocation?

Apply data analytics for better demand forecasting and stock management.

How to address delayed replenishment of essential items?

Set automated reorder points to ensure timely restocking of supplies.

What method can improve tracking storage and shipment statuses?

Utilize integrated inventory systems for real-time shipment tracking.

How does efficient inventory management improve customer satisfaction?

Reduces stockouts and enhances order fulfillment speed, boosting customer loyalty.

Further Reading

In conclusion, the optimization of your inventory management can be the key to elevating your clinical lab's efficiency and profitability. By implementing strategies like an Enterprise Resource Planning (ERP) system and leveraging real-time analytics, you can significantly reduce wastage, minimize errors, and ensure timely replenishments. This tutorial has equipped you with the insights to tackle common challenges and enhance your overall inventory control. Let’s discuss how we can help you implement these strategies effectively. Reach out to David, our CEO, via WhatsApp at https://wa.me/84937869689, or email our Ecommerce Project Consultant at [email protected]. For tailored solutions, request a quotation at https://cmsmart.net/home/teams/#contact. Together, we can transform your operations and drive your business to new heights!

David Nguyen

Founder & CEO, Cmsmart Ecommerce (a division of Netbase JSC)

With over 20 years of experience in business strategy and ecommerce technology, David Nguyen has empowered hundreds of online retailers around the world to scale smarter and faster. As the visionary behind Cmsmart, he has driven the development of personalization solutions and product-customization tools that deepen customer engagement and boost average order values. His commitment to creativity, practical strategy and results-driven outcomes has earned Cmsmart a reputation as a trusted partner for small, medium and enterprise-level ecommerce brands.

Contact Me via WhatsApp: https://wa.me/84937869689

Email: [email protected]

Let’s talk about how your ecommerce store can grow.

If you're ready to transform your store with tailored solutions that drive engagement and revenue, send me a message on WhatsApp or email today — and our team will connect with you right away.