TABLE OF CONTENTS

TABLE OF CONTENTS

Other Usefull Contents

You can see many success stories from our customers, and you may be one of them in the future

Unlock the Power of Mobile Commerce: Propel Your Business Forward

Read MoreDiscover how to harness mobile commerce to enhance your business growth. Learn strategies for optimizing the mobile shopping experience and increasing consumer engagement.

Read MoreDiscover the benefits of mobile commerce and how it can transform your business. Learn effective strategies for maximizing sales and customer engagement through mobile-optimized shopping experiences.

Read More

Are you grappling with the complexities of managing your Maintenance, Repair, and Operations (MRO) inventory? In today’s competitive landscape, companies that streamline their MRO practices are reaping significant rewards. According to industry estimates, optimizing MRO inventory management can reduce costs by up to 25%. Take the case of ABC Manufacturing from the USA. Faced with severe delays in maintenance due to inaccurate inventory records, they turned to Cmsmart to revamp their inventory management system. By harnessing tailored KPIs and leveraging advanced inventory management software, ABC Manufacturing not only improved their inventory accuracy but also experienced a notable uptick in operational efficiency.

Effective MRO inventory management is not just about keeping track of stock; it’s about ensuring that every component is available when needed, which ultimately boosts productivity. Maintaining accurate inventory records, avoiding overstock situations, and accurately forecasting demand are crucial elements of success that can be simplified with the right metrics and tools. For instance, increasing your inventory turnover rate and tracking your fill rate can create a more fluid and efficient operation. In this tutorial... we will delve deep into the essential KPIs for MRO inventory management that can transform your supply chain efficiency and performance.

The Reality of MRO Inventory Management

Missed maintenance windows due to low inventory accuracy, Delayed repairs stemming from inaccurate inventory records, Overstock and the resultant capital tie-up, Challenges in accurate demand forecasting for inventoryWhat if you never had to worry about inventory accuracy, overstock, or missing maintenance windows ever again? Its possible with MRO Inventory Management KPIs.

MRO Inventory Management: Keys to Success

Managing Maintenance, Repair, & Operations (MRO) inventory may seem tedious, but it’s integral to business operations. Key performance indicators (KPIs) for MRO inventory management not only refine your processes but also ensure efficiency and reliability.

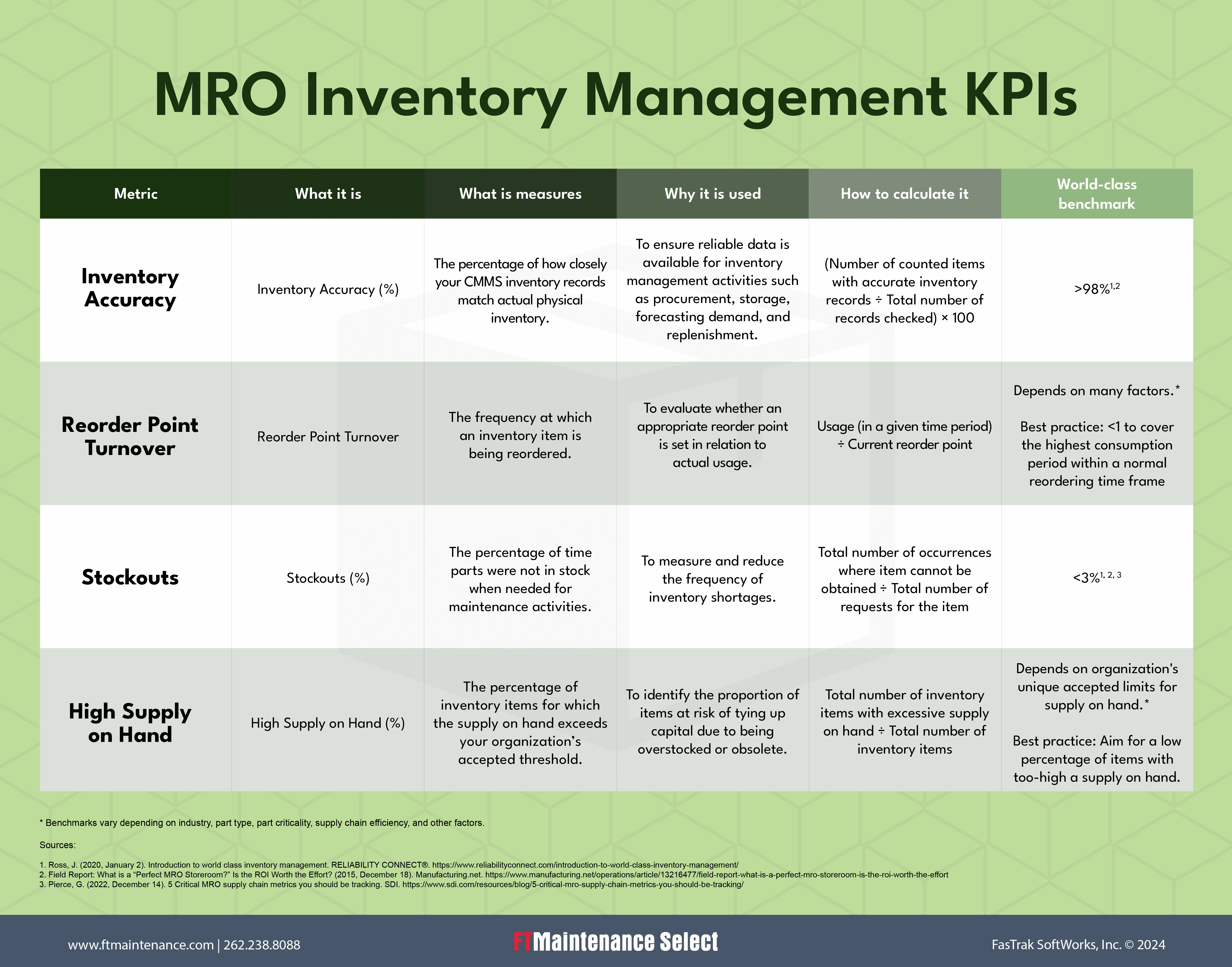

MRO Inventory Metrics Simplified

Leveraging Maintenance, Repair & Operations KPIs can help curb excessive spending and enhance inventory accuracy. Consider integrating these metrics:

Expert Strategies for Effective MRO Management

Streamlining your MRO inventory management can mitigate risks and increase operational efficiency. Focus on:

Internal and External Link Resources

For further exploration, check out our resources on KPIs for Inventory Accuracy, Optimizing MRO Inventory, and Supply Chain KPI Benchmarking. These guides provide deep insights into enhancing your inventory control strategies.

In summary: MRO inventory management, when properly strategized with KPIs, reduces the risk of unexpected maintenance delays and overstock issues. By implementing these strategies, your operations will run smoother, cost-effectively, and more predictably. Next, lets explore how integrated technology solutions can further optimize MRO workflows.Getting to Know MRO Inventory Management KPIs

Missed maintenance windows due to low inventory accuracy?Inaccurate inventory records often lead to delayed repairs, causing overstock and unnecessary capital tie-up, and posing challenges in accurate demand forecasting. Understanding MRO (Maintenance, Repair, and Operations) Inventory Management KPIs is crucial to addressing these issues.

Understanding the Role of Maintenance, Repair, and Operations KPIs

MRO KPIs streamline process efficiency, helping businesses maintain duly aligned and available inventory stocks. These indicators ensure that every part, tool, or supplementary component is in place when needed, minimizing downtime and preventing overstock.

Unveiling the Importance of Inventory Performance Indicators

Inventory Performance Indicators pinpoint the efficacy of your inventory management processes. They manage the delicate balance of stock levels, preventing both shortages and excess stock, which is critical for maintaining operational efficiency.

Exploring In-Depth MRO Inventory Metrics

Dive deep into MRO inventory metrics to find insights that drive business decisions. These metrics not only assist in maintaining current asset levels but also in predicting future demands through historical data analysis.

For comprehensive insights into boosting inventory efficiency, consider exploring topics like KPIs for Inventory Accuracy, Optimizing MRO Inventory, Supply Chain KPI Benchmarking, Understanding Reorder Points, and Improving Inventory Forecasting.

In summary: Efficient MRO inventory management through effective KPIs fosters operational excellence, propelling businesses to meet and exceed industry standards. Next, delve into advanced strategies for optimizing MRO Inventory.Critical MRO Inventory Management KPIs

Missed maintenance windows due to low inventory accuracy? Its a common hurdle for businesses managing Maintenance, Repair & Operations (MRO) inventory. Delayed repairs and overstock issues often stem from outdated inventory records and inaccurate demand forecasting. Heres how you can overcome these challenges with key performance indicators (KPIs).The Significance of Inventory Accuracy

Inventory accuracy is crucial for minimizing capital tie-up and ensuring timely repairs. Accurate records support effective inventory forecasting and demand planning, preventing both stockouts and overstock. Implementing precise inventory metrics can significantly reduce unnecessary spending.

Reorder Point Turnover: The Need of the Hour

Identifying the optimal reorder point is essential to balance between too much and too little inventory. This KPI helps in adjusting order quantities to align with actual consumption rates.

The Power of Inventory Optimization in MRO Management

Optimizing inventory involves using strategic forecasting and procurement to ensure the right stock at the right time. This reduces excess inventory and improves operational efficiency.

- Use predictive analytics to anticipate future demand.

- Implement just-in-time inventory systems to enhance operational fluidity.

In summary: Implementing these critical MRO inventory management KPIs facilitates smoother operations and lower costs. For a deeper dive, explore our guides on KPIs for Inventory Accuracy, Optimizing MRO Inventory, and Supply Chain KPI Benchmarking. Next, let’s explore actionable strategies for improving inventory forecasting in our upcoming section.MRO Inventory Management within the Supply Chain Context

Missed maintenance windows due to low inventory accuracy, delayed repairs stemming from inaccurate inventory records, overstock, and the resultant capital tie-up are common challenges in MRO inventory management.MRO (Maintenance, Repair, and Operations) inventory management plays a crucial role in ensuring efficient supply chain operations. Effective inventory management not only mitigates downtime but also enhances the performance of supply chain KPIs.

Understanding Supply Chain Management KPIs

Ascertaining the Role of MRO in Supply Chain Efficiency

Understanding how MRO inventory impacts supply chain performance is essential. When managed well, it prevents disruptions and ensures seamless operations, directly influencing the efficiency and reliability of the supply chain.

Impact of Supply Chain Management on MRO Inventory

Internal links: KPIs for Inventory Accuracy, Optimizing MRO Inventory, Supply Chain KPI Benchmarking, Understanding Reorder Points, Improving Inventory Forecasting.

In summary: Addressing MRO inventory management within the context of the supply chain is indispensable for operational success. The subsequent section delves into advanced inventory forecasting techniques to continue honing efficiency and productivity.Leveraging Computerized Maintenance Management Systems (CMMS) for MRO

Are missed maintenance windows, delayed repairs, and inventory overstocking hindering your operations?Many businesses struggle with maintaining inventory accuracy, which can lead to substantial capital tie-up and forecasting challenges. This is where Computerized Maintenance Management Systems (CMMS) can truly make a difference.

The Importance of CMMS in MRO Inventory Management

A CMMS is essential in transforming how you manage MRO (Maintenance, Repair, and Operations) inventory. By automating and optimizing inventory records, it enhances productivity and cuts unnecessary costs. According to a report by MarketsandMarkets, the global CMMS market is projected to reach USD 1.9 billion by 2025, driven by the increasing need for improved equipment uptime and controlled inventory expenses.

Features of an Efficient CMMS for MRO Inventory

Not all CMMS solutions are created equal. Here are key features to look for:

Choosing an Effective CMMS that Meets Your MRO Needs

Finding the right CMMS that fits your business can be challenging. Consider these steps:

- Define Business Goals: Align your CMMS selection with strategic business objectives, such as improving Maintenance KPIs.

- Evaluate User-Friendliness: Ensure the system is intuitive for seamless user adoption.

- Assess Customization Options: Look for software that caters to your specific industry needs.

- Review Client Testimonials: Learn from other businesses success stories to gauge potential benefits.

In summary: Leveraging a CMMS can greatly enhance your MRO inventory management efficiency, reduce costs, and improve accuracy, paving the way for proactive maintenance strategies. Next, let’s dive into the "KPIs for Inventory Accuracy" to further optimize your MRO framework.Streamlining Inventory Records and Demand Planning in MRO

Struggling with missed maintenance windows due to low inventory accuracy or delayed repairs from inaccurate inventory records?The ripple effects of overstock and capital tie-up and the challenges of accurate demand forecasting are common in the Maintenance, Repair & Operations (MRO) sector.

Overcoming the Challenges of Inaccurate Inventory Records

Demand Planning Strategies for MRO Inventory Management

Forecasting Inventory Demand: The Silver Bullet for MRO Management

In summary, addressing these core issues with actionable strategies can significantly enhance your MRO inventory management. To delve deeper into related aspects, explore our resources on KPIs for Inventory Accuracy, Optimizing MRO Inventory, and Supply Chain KPI Benchmarking.

Next Steps: As we explore further, discover how understanding reorder points can play a pivotal role in improving inventory forecasting efficiency and overall supply chain resilience.Effective Procurement and Management of MRO Inventory

Struggling with missed maintenance windows and delayed repairs due to inventory inaccuracies? You’re certainly not alone.Many businesses grapple with the challenges of maintaining accurate inventory records, facing issues like capital tie-up from overstock and inaccurate demand forecasting. Here’s how you can effectively handle the procurement and management of Maintenance, Repair & Operations (MRO) Inventory.

Importance of Efficient Procurement of MRO Inventory

Efficient procurement of MRO inventory is vital for the seamless operation of any organization. It helps maintain optimal stock levels, ensuring that essential maintenance tasks are not delayed due to inventory shortages. By implementing a robust inventory management system, companies can streamline their procurement processes, reduce waste, and improve overall efficiency.

Key Steps in Managing MRO Inventory Efficiently

Best Practices and Essential Considerations for Procurement and Management of MRO Inventory

Managing MRO inventory effectively involves more than just keeping track of stock levels. Here are some best practices that can enhance your procurement and inventory strategies:

For a deeper dive into optimizing your MRO inventory, explore resources like supply chain KPI benchmarking and inventory forecasting improvements .

In summary: Adopting these strategies will not only streamline your MRO inventory management but also prepare your operations for scalable growth. Next, let’s explore how to establish and monitor KPIs for inventory accuracy effectively.Trends and Future Predictions in MRO Inventory Management

Missed maintenance windows due to low inventory accuracy? You’re not alone.Many businesses face similar challenges, such as delayed repairs stemming from inaccurate inventory records or overstock leading to capital tie-up.

Latest Trends in MRO Inventory Management

Maintenance, Repair & Operations (MRO) inventory management is evolving rapidly. Companies are increasingly adopting advanced computerized maintenance management systems (CMMS) to enhance inventory records accuracy and optimize maintenance schedules. This shift helps reduce downtime and improve equipment reliability.

Predicted Future Trends in MRO

Looking ahead, the landscape of MRO inventory management will likely continue to advance. Innovations are paving the way for more sophisticated demand planning and inventory forecasting capabilities.

How to Future-Proof Your MRO Inventory Management System

To stay ahead, businesses must adapt their MRO inventories to be flexible and resilient. Here are some actionable strategies to future-proof your system:

For more details on enhancing your inventory accuracy, check out our guide on KPIs for Inventory Accuracy.

In summary: Embracing the latest technology and anticipating future trends will ensure your MRO inventory management system remains effective. Next, let’s delve into strategies for optimizing your MRO inventory for maximum efficiency and cost-effectiveness.Frequently Asked Questions

Struggling with missed maintenance windows due to low inventory accuracy?Many businesses grapple with delayed repairs stemming from inaccurate inventory records, leading to overstock and resultant capital tie-up. Additionally, challenges in accurate demand forecasting for inventory can exacerbate these issues.

Common Questions About MRO Inventory Management KPIs

Maintenance, Repair & Operations KPIs, also known as MRO Inventory Metrics, are crucial for optimizing inventory performance. Here, we address five common questions to help you better manage your MRO inventory.

1. How can I improve inventory accuracy?

Improving inventory accuracy involves regular audits and utilizing a Computerized Maintenance Management System (CMMS) to streamline inventory records and audits.

2. What strategies help in avoiding overstock?

Poor demand planning leads to overstock, tying up capital unnecessarily. Efficient use of MRO Inventory Metrics can help mitigate this.

3. How do I forecast demand accurately?

Accurate forecasting can be achieved by integrating MRO metrics into demand planning.

4. What KPIs are critical for monitoring MRO inventory?

5. How can I streamline procurement?

Efficient procurement processes can enhance inventory management.

In summary: Mastering MRO inventory management through strategic KPI analysis helps businesses achieve seamless operations. Next, lets dive into advanced techniques like Optimizing MRO Inventory and Understanding Reorder Points to further boost your efficiency.

This streamlined FAQ section equips your business with the crucial insights needed to refine your inventory management processes, addressing key pain points while setting the stage for optimized operations.FAQ Section: Troubleshooting and Pro Tips

What are MRO inventory management KPIs?

They are metrics used to evaluate the effectiveness and efficiency of maintenance, repair, and operations inventories.

How does low inventory accuracy affect maintenance windows?

Inaccurate inventory levels can lead to missed maintenance windows as required parts may not be available.

What issues arise from delayed repairs due to inaccurate records?

Delays in repairs can lead to extended equipment downtime, resulting in lost productivity and increased costs.

How can overstock impact business finances?

Overstock can tie up capital, leading to increased holding costs and reduced cash flow.

Why is accurate demand forecasting important for inventory?

It helps to ensure optimal stock levels, reducing costs associated with excess or insufficient inventory.

What challenges exist in maintaining accurate inventory records?

Common challenges include manual recording errors, system discrepancies, and untracked inventory theft.

Further Reading

In this tutorial, we've uncovered the critical role MRO Inventory Management KPIs play in optimizing your supply chain efficiency and overall performance. Implementing these metrics can help you achieve accurate inventory levels, eliminate overstock, and prevent costly missed maintenance windows. What if you could transform your operational processes to ensure reliability and cost savings? Let’s discuss how we can help you implement these essential KPIs and elevate your business. Reach out to David directly via WhatsApp at https://wa.me/84937869689. For inquiries or to explore tailored solutions, email our Ecommerce Project Consultant at [email protected]. You can also request a quotation through our website at https://cmsmart.net/home/teams/#contact. Don't let inefficiencies hinder your growth; let’s transform your inventory management today!

David Nguyen

Founder & CEO, Cmsmart Ecommerce (a division of Netbase JSC)

With over 20 years of experience in business strategy and ecommerce technology, David Nguyen has empowered hundreds of online retailers around the world to scale smarter and faster. As the visionary behind Cmsmart, he has driven the development of personalization solutions and product-customization tools that deepen customer engagement and boost average order values. His commitment to creativity, practical strategy and results-driven outcomes has earned Cmsmart a reputation as a trusted partner for small, medium and enterprise-level ecommerce brands.

Contact Me via WhatsApp: https://wa.me/84937869689

Email: [email protected]

Let’s talk about how your ecommerce store can grow.

If you're ready to transform your store with tailored solutions that drive engagement and revenue, send me a message on WhatsApp or email today — and our team will connect with you right away.