TABLE OF CONTENTS

TABLE OF CONTENTS

Other Usefull Contents

You can see many success stories from our customers, and you may be one of them in the future

Unlock the Power of Mobile Commerce: Propel Your Business Forward

Read MoreDiscover how to harness mobile commerce to enhance your business growth. Learn strategies for optimizing the mobile shopping experience and increasing consumer engagement.

Read MoreDiscover the benefits of mobile commerce and how it can transform your business. Learn effective strategies for maximizing sales and customer engagement through mobile-optimized shopping experiences.

Read More

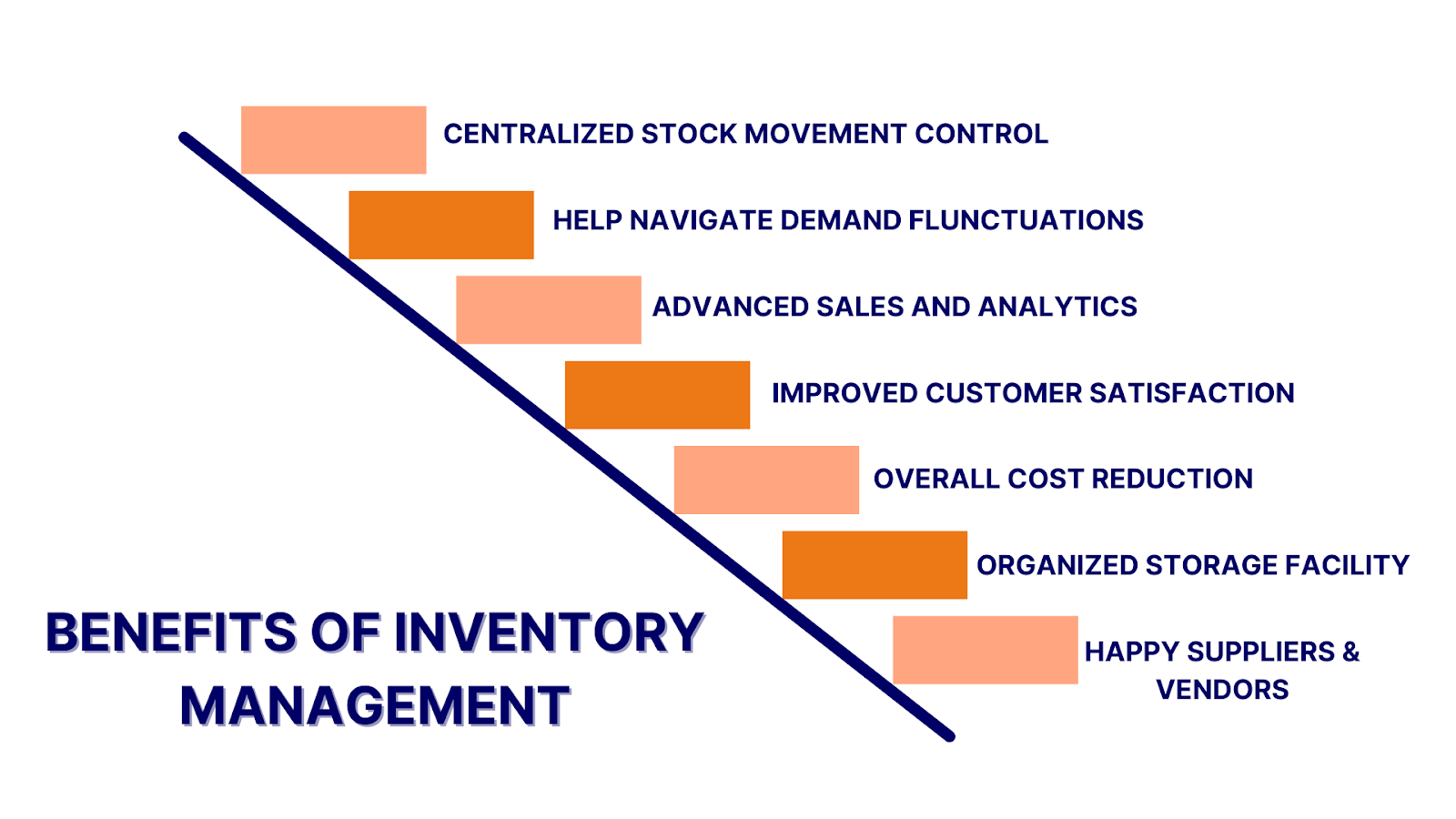

Did you know that businesses that implement effective inventory management can see a reduction in storage costs by 20-50%? In today's competitive ecommerce landscape, mastering inventory management is not just a choice; it's a necessity. Companies like ABC Fashion from Canada, a leader in the apparel industry, struggled with stock management, leading to frequent stockouts and dissatisfied customers. By partnering with Cmsmart and utilizing our advanced inventory solutions, they transformed their inventory from a potential liability to a streamlined asset, automating reorder systems and enhancing supplier relationships. This shift not only improved their efficiency but also showcased how strategic inventory management can significantly boost profitability and customer satisfaction.

According to industry reports, effective inventory control is a game-changer for ecommerce businesses, enabling them to not only save costs but also enhance service delivery. By leveraging technology and data-backed strategies, you too can optimize your operations and prevent costly stockouts. Learn how proactive inventory tracking can redefine your business, just as it did for ABC Fashion. In this tutorial, we’ll explore the art and science of inventory management, giving you the tools to streamline your business like never before.

The Art and Science of Inventory Management

Transforming Inventory from Liability to Asset: Master the Art and Science of Inventory ManagementDid you know that with effective inventory management, you can turn your stock from a potential liability into a thriving asset? By implementing key strategies, businesses can effectively manage supplier relationships, avoid stockouts, track products origins and destinations, and configure efficient reorder systems to optimize efficiency and profitability.

Strategies for Effective Inventory Management

Integrating Expert Techniques

In Summary: By leveraging effective inventory management strategies and tools, you can transform your inventory into a valuable asset. For insights into understanding supplier relationships and managing customer segmentation, see our guides on understanding supplier relationships and managing customer segmentation in inventory . Next, well explore effective SKU management strategies.Exploring the Basics of Inventory Management

Struggling to keep track of your inventory and fulfill orders smoothly? You’re not alone.

Managing supplier relationships effectively, avoiding inventory stockouts, tracking product origin and destination, and configuring efficient reorder systems are crucial challenges businesses face today.

Definition of Inventory Management and its Importance

Inventory management is the process of overseeing and controlling the ordering, storage, and use of components that a company uses in the production of the items it sells. It also involves managing the quantities of finished products for sale. Effective inventory management is crucial for ensuring that a business can meet customer demand without delay while keeping costs down and preventing overstock.

Understanding Terms: Stock Control, Inventory Tracking, and Stockout Prevention

Exploring Tools: Reorder Systems, Supplier Timelines, Tracking Product Origin and Destination

Implementing effective reorder systems and maintaining open communication with suppliers ensures a seamless restocking process.

For advanced strategies on managing your inventory, consider our guides on understanding supplier relationships, managing customer segmentation in inventory, and effective SKU management strategies.

In summary: Understanding the basics of inventory management allows you to streamline operations and prevent costly stockouts. Next, we delve into advanced techniques for enhancing supplier relationships and optimizing SKU management.Importance of Robust Supplier Relationships

Managing supplier relationships effectively is a cornerstone of successful inventory control, helping to prevent stockouts and ensuring timely reorder systems.Understanding and nurturing your supplier relationships can greatly enhance your ability to manage inventory, track product origins and destinations, and streamline reorder configurations.

What is a Supplier Relationship and why is it Crucial?

Supplier relationships refer to the connections and interactions between a business and its suppliers. They are crucial because they ensure a steady supply of products, maintain quality standards, and optimize procurement costs. Effective supplier management mitigates risks such as inventory stockouts and enhances inventory tracking capabilities.

Benefits of Establishing Strong Supplier Relationships

Best Practices for Strengthening Supplier Relationships

In summary, robust supplier relationships are integral to efficient stock control and inventory management. By implementing these practices, businesses can effectively navigate market challenges and drive substantial growth. Next, we will explore understanding supplier relationships in our subsequent section which delves deeper into managing customer segmentation in inventory and effective SKU management strategies.

The Power of Customer Segmentation

Struggling with inventory stockouts? You’re not alone.Many businesses grapple with efficient supplier relationships and inventory tracking, crucial for ensuring stock availability and optimizing reorder systems.

Understanding the Role of Customer Segmentation in Inventory Control

Customer Segmentation is a powerful tool that categorizes your customer base into distinct groups, allowing for more precise stock control. By understanding purchasing behaviors and preferences, businesses can tailor inventory to meet actual demand, thereby reducing stockouts and excess stock.

How Customer Segmentation Enhances Supply Chain Efficiency

By aligning inventory levels with customer group needs, businesses can minimize logistics costs and enhance supply chain efficiency. This targeted approach reduces waste and ensures that warehouse resources are used more effectively.

Effective Strategies for Implementing Customer Segmentation in Inventory Management

- Regularly update segments based on purchasing trends

- Integrate advanced inventory management software

- Work closely with suppliers for timely stock replenishment

In summary: By implementing effective customer segmentation strategies, you not only tackle the issue of inventory stockouts but also create a responsive and efficient inventory management system. Next, we will dive into understanding supplier relationships to further enhance your operational efficiency. Check out our related content on understanding supplier relationships, managing customer segmentation in inventory, and effective SKU management strategies.Optimizing SKU and Catalog Management

Struggling to maintain seamless eCommerce operations due to unreliable supplier timelines and inventory stockouts?Managing product SKUs and catalogs efficiently plays a vital role in preventing stockouts, ensuring smooth supplier collaborations, and enhancing the shopper experience.

Essentials of SKU Management and Its Impact on Inventory

Effective SKU management is crucial for stock control and maintaining robust inventory systems. Each product variant should have a unique SKU, making it easier to track the origin and destination within the supply chain.

Importance of Robust Catalog Management in Ecommerce

A comprehensive catalog management system ensures consistency and accuracy across all sales channels, which is paramount for enhancing user experience and driving sales.

Tips and Tricks for Streamlining SKU and Catalog Management

Streamlining your SKU and catalog management processes not only reduces administrative tasks but also enhances your ability to respond rapidly to market changes.

- Utilize inventory control software that integrates with point-of-sale systems to track real-time inventory levels

- Create an efficient reorder system to maintain an optimal inventory balance

- Establish regular communication with suppliers to better anticipate potential disruptions

In summary: Implementing these strategies for SKU and catalog management ensures your eCommerce operations remain agile and efficient. Next, lets explore advanced catalog strategies .Understanding and Responding to Inventory-Related Pain Points

Managing supplier relationships effectively and responding to inventory challenges can be daunting for any eCommerce business.Common Challenges in Managing Supplier Relationships

Supplier relationships are the backbone of your inventory management strategy. Strong communication and mutual goals help in navigating common hurdles like delivery delays or quality inconsistencies.

Avoiding Inventory Stockouts: Key Strategies

Prevention of stockouts is critical to maintaining customer satisfaction and business continuity.

Efficient Reorder Systems: Setting up for Success

Configuring an efficient reorder system is vital for seamless operations and can substantially improve your business responsiveness.

Tracking Product Origin and Destination: Why It Matters

Tracking your products origin and destination is crucial for compliance and optimization of your supply chain.

- Ensure that your inventory management system supports precise tracking of product batches and their destinations.

- Utilize tools like barcoding and RFID to enhance product traceability throughout the supply chain.

- Maintain detailed records of product origins to support any product recalls or quality assurance processes.

In summary: By addressing these inventory-related pain points, you enhance operational efficiency and customer satisfaction. For further information, explore our guides on understanding supplier relationships, managing customer segmentation in inventory, and effective SKU management strategies. Next, we delve into advanced techniques for managing customer segmentation in inventory.Making Sense of the Product Lifecycle

Managing supplier relationships effectively while avoiding inventory stockouts can feel like juggling multiple spinning plates.In inventory management, tracking product origins and destinations, and configuring efficient reorder systems are key to maintaining balance. An integral concept that aids in this process is understanding the product lifecycle.

Decoding the Concept of Product Lifecycle in Inventory Management

Understanding the product lifecycle is crucial in effective inventory control. This concept refers to the stages a product goes through from introduction to withdrawal from the market. Each stage—introduction, growth, maturity, and decline—requires different inventory strategies.How the Product Lifecycle Impacts Inventory Decision-Making

The product lifecycle directly influences inventory decisions, impacting how much stock to hold and when to ramp up or slow down production. By aligning inventory strategies with each lifecycle stage, businesses can enhance inventory tracking, supplier timelines, and stockout prevention.Effective Ways to Leverage the Product Lifecycle to Optimize Stock Control

Leveraging the product lifecycle in stock control involves using precise strategies that align with each phase’s characteristics.- Implement advanced inventory tracking systems for real-time data on product movement and demand changes.

- Collaborate closely with suppliers to adjust orders according to lifecycle stages and market conditions.

- Use internal audits to assess inventory accuracy and adjust forecasts as needed.

As we wrap up our exploration of product lifecycle management, remember that integrating these strategies can mitigate common business pain points like stockouts and inefficient reorder systems. Next, let’s delve into understanding supplier relationships, managing customer segmentation in inventory, and effective SKU management strategies.Future of Inventory Control: Trends and Perspectives

Struggling to manage your inventory efficiently and curious about whats next?Many enterprises face common challenges like managing supplier relationships and avoiding inventory stockouts, which are crucial for operational success.

Current Trends Influencing Inventory Management

Inventory control is evolving with emerging technologies and dynamic market demands. Heres how current trends are shaping the future of stock control:

Projections and Predictions: The Future of Inventory Control

The inventory landscape is set to transform further with these projections:

Tools and Strategies for Future-Proofing Your Inventory Management Systems

To stay ahead, companies need to adopt robust tools and strategies:

For further strategies, explore guides on understanding supplier relationships, managing customer segmentation in inventory, and effective SKU management strategies.

In summary: Staying informed and adopting innovative practices will secure your inventorys future. Up next, delve into personalizing inventory management to enhance customer experience.Frequently Asked Questions

Struggling to manage your inventory efficiently? Its a common challenge faced by many businesses.From handling supplier relationships to preventing inventory stockouts, effective management is key to maintaining a streamlined operation and ensuring customer satisfaction.

Understanding Common Inventory Management Questions

Optimizing Supplier Relationships and Preventing Stockouts

Establish clear communication channels with suppliers to manage timelines and expectations effectively. Implementing advanced inventory control systems can significantly enhance stock monitoring and reorder processes.Tracking and Configuring Efficient Systems

Utilize tools to track product origin and destination, ensuring precise data for better inventory decisions. Configuration of reorder systems can automate the process, saving time and reducing errors. For further insights on enhancing your operations, explore our guides on understanding supplier relationships, managing customer segmentation, and effective SKU management strategies. In summary: By leveraging these strategies, your business can achieve efficient inventory management, reducing costs and improving customer satisfaction. Next, let’s delve into optimizing supplier dynamics to enhance overall operational effectiveness.Further Reading

In conclusion, an advanced inventory management system can significantly elevate your business operations, transforming inventory from a potential liability into a strategic asset. By implementing effective stock control methods and utilizing technology for seamless tracking, you can enhance efficiency and customer satisfaction while cutting costs. Don’t wait to take advantage of these strategies; let’s discuss how we can help you implement them effectively. Reach out to David on WhatsApp at this link, or contact our Ecommerce Project Consultant via email at [email protected]. For tailored solutions, request a quotation at this page. Join us in transforming your business and watch your inventory work for you!

David Nguyen

Founder & CEO, Cmsmart Ecommerce (a division of Netbase JSC)

With over 20 years of experience in business strategy and ecommerce technology, David Nguyen has empowered hundreds of online retailers around the world to scale smarter and faster. As the visionary behind Cmsmart, he has driven the development of personalization solutions and product-customization tools that deepen customer engagement and boost average order values. His commitment to creativity, practical strategy and results-driven outcomes has earned Cmsmart a reputation as a trusted partner for small, medium and enterprise-level ecommerce brands.

Contact Me via WhatsApp: https://wa.me/84937869689

Email: [email protected]

Let’s talk about how your ecommerce store can grow.

If you're ready to transform your store with tailored solutions that drive engagement and revenue, send me a message on WhatsApp or email today — and our team will connect with you right away.