TABLE OF CONTENTS

TABLE OF CONTENTS

Other Usefull Contents

You can see many success stories from our customers, and you may be one of them in the future

Unlock the Power of Mobile Commerce: Propel Your Business Forward

Read MoreDiscover how to harness mobile commerce to enhance your business growth. Learn strategies for optimizing the mobile shopping experience and increasing consumer engagement.

Read MoreDiscover the benefits of mobile commerce and how it can transform your business. Learn effective strategies for maximizing sales and customer engagement through mobile-optimized shopping experiences.

Read More

Did you know that the global Warehouse Management System (WMS) market is projected to soar from $2.3 billion in 2020 to a staggering $4.9 billion by 2027? This rapid growth highlights the urgent need for businesses to streamline their warehouse operations. For instance, consider the case of Javacoa Inc., a thriving gourmet coffee company from Australia. They faced significant setbacks during peak seasons, grappling with inefficient inventory management that resulted in delayed shipments and unhappy customers. By implementing Cmsmart’s WMS, they transformed their logistics challenges into streamlined operations, achieving a remarkable 40% reduction in order processing time. This is a game changer in an industry where timely fulfillment is key to customer satisfaction.

As organizations like Javacoa demonstrate, integrating a powerful Warehouse Management System is not just a luxury but a necessity to maintain competitive advantage. In this tutorial, we will explore how a WMS not only enhances storage efficiency and order accuracy but also optimizes task management to adapt seamlessly to seasonal fluctuations. If you're looking to learn more about enhancing your logistics, consider reading our resources on enhancing operational efficiency or transforming your operations with advanced inventory management. Join us as we delve into the powerful features of a WMS that can revolutionize your warehouse capabilities.

Why a Warehouse Management System (WMS) matters for your organization

Imagine saving countless hours and reducing errors by automating your warehouse management processes. A WMS can make this a reality.Many organizations struggle with inventory allocation challenges, inefficiencies in storage, and inaccuracies in order fulfillment. These issues can lead to stressful shipping operations, especially during seasonal inventory fluctuations.

Optimize Your Warehouse Management

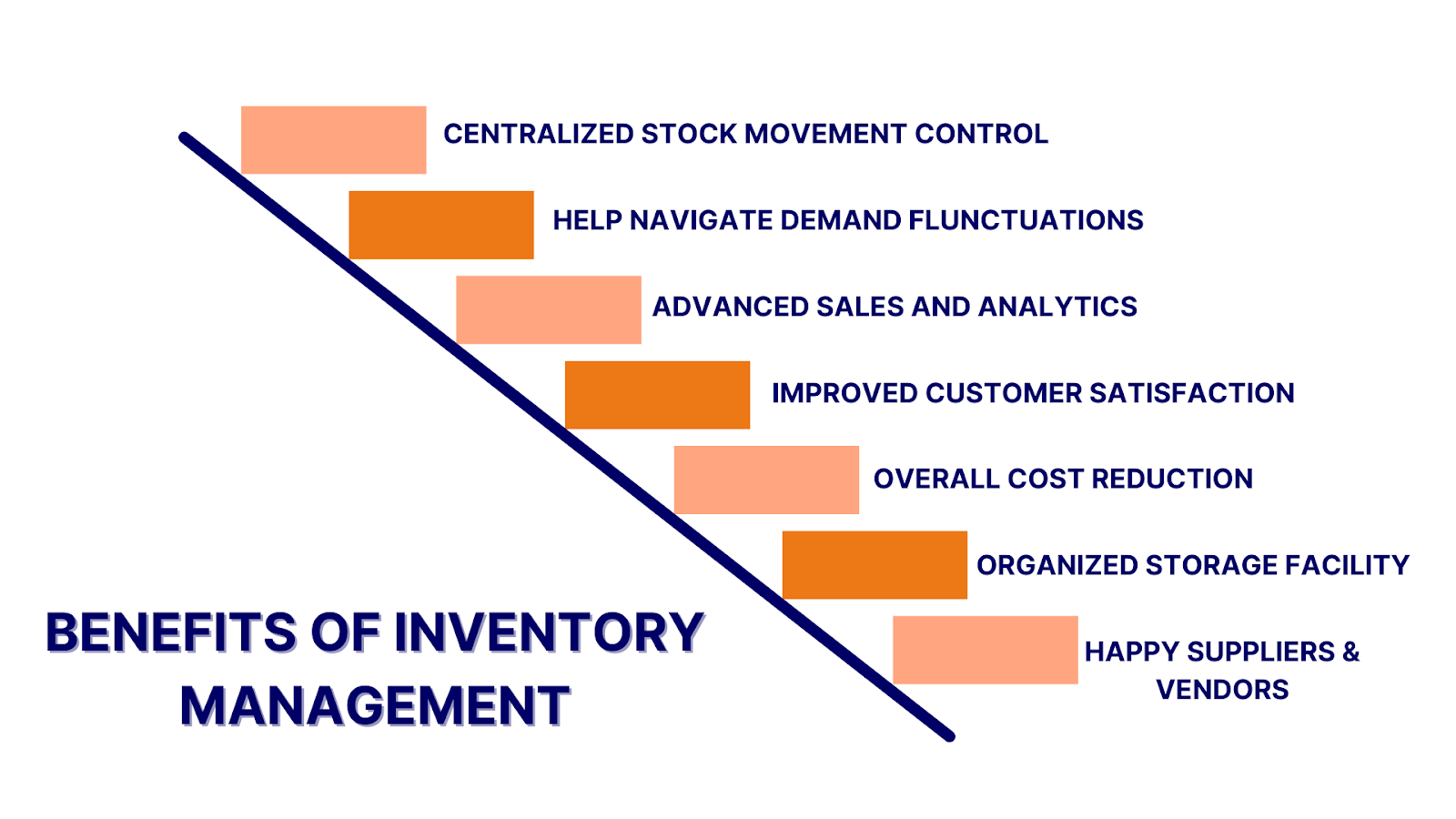

By integrating a Warehouse Management System (WMS), businesses can significantly improve their overall operations. Here are some key advantages of adopting a WMS:Real-World Impact of WMS

Many companies have experienced dramatic improvements by implementing a WMS. One client shared, In addition to enhancing accuracy and efficiency, a WMS helps streamline the shipping process, ensuring timely deliveries while reducing labor costs.Explore the Benefits Further

To address common business pain points, consider looking into the importance of customized warehouse design, or learn about advancements in inventory tracking to improve your operational efficiency further. Our guides on methods to streamline picking and packing and automating the shipping process will also be beneficial. In summary: A robust Warehouse Management System is essential for optimizing storage and enhancing order fulfillment accuracy. As we move forward, let’s explore how customizing your warehouse design can lead to even greater operational success.Understanding Warehouse Management Systems (WMS)

Struggling with inventory allocation, storage inefficiencies, and inaccuracies in order fulfillment? You’re not alone.Many businesses face these critical challenges, leading to time-consuming picking and packing processes and stressful shipping operations that can hinder overall productivity.

Defining a Warehouse Management System (WMS)

A Warehouse Management System (WMS) is a software solution that enhances warehouse operations by optimizing inventory management. It supports businesses in efficiently tracking, managing, and controlling their warehousing processes. By automating tasks such as inventory allocation, order fulfillment, and shipping, businesses can significantly improve storage efficiency and accuracy.History and Importance of WMS in Current Logistic Operations

The adoption of WMS technology has significantly transformed warehouse logistics over the past few decades. Initially designed to handle basic inventory management, WMS has evolved to support complex operations, enabling businesses to respond swiftly to market fluctuations and customer demands. - Most companies measure success through reduced operational costs and increased order fulfillment accuracy. - According to a report by MarketsandMarkets, the WMS market is expected to reach $10.9 billion by 2025, growing at a CAGR of 14.2% from 2020 to 2025.Synonyms Explained: WMS, Warehouse Management, Inventory Management System

Understanding the language of warehouse management is crucial. Here are some common terms associated with WMS:Pro Tips for Implementing WMS

For those considering or already utilizing WMS, following expert advice can unlock additional benefits:Conclusion

By leveraging a WMS, businesses can tackle common warehousing challenges, leading to increased efficiency and better customer satisfaction. Transitioning to automated solutions enhances task optimization and creates a smarter logistics operation. Next, we will delve into the importance of customized warehouse design, advancements in inventory tracking, methods to streamline picking and packing, and automating the shipping process to further improve your logistics operations.Why Inventory Tracking is Crucial in WMS

Are inventory allocation challenges and inefficiencies in storage holding your warehouse operations back?Many businesses struggle with handling seasonal inventory fluctuations, inaccuracies in order fulfillment, and time-consuming picking and packing processes. Integrating effective inventory tracking is essential to overcome these hurdles and streamline your warehouse management system (WMS).

Overview of Inventory Tracking Technologies

Modern inventory tracking technologies like RFID and barcodes have revolutionized the way businesses manage their inventory. These tools not only improve accuracy but also enhance efficiency across various warehouse operations. Implementing these technologies can result in:Importance of Tracking Inventory Efficiently

Efficient inventory tracking not only addresses logistics headaches but also supports overall business performance. Here are key benefits of implementing a robust WMS:Case Studies of Improved Warehouse Management through Effective Inventory Tracking

Real-world examples provide strong evidence of the positive impact of effective inventory tracking. Companies that have adopted these technologies report remarkable improvements in their operations. For instance, a leading retail chain saw a 25% reduction in pick times by sticking to meticulous inventory annotations. Incorporating advanced inventory management systems not only alleviates stress during peak seasons but also enhances fulfillment capabilities. By ensuring accurate tracking and effective resource allocation, your business can efficiently manage fluctuations and improve customer satisfaction. In summary: Implementing superior inventory tracking technologies is pivotal for overcoming common warehouse challenges. Next, let’s explore the importance of customized warehouse design and delve into the advancements in inventory tracking for further optimization of your warehouse operations.Improving Warehouse Design and Layout

Struggling with inefficient inventory allocation and chaotic warehouse operations? Youre not alone.Many businesses face significant challenges like inaccuracies in order fulfillment, time-consuming picking and packing processes, and the stress of handling seasonal inventory fluctuations.

Importance of Customized Warehouse Design

A tailored warehouse design is crucial for tackling issues such as storage inefficiencies and operational bottlenecks. Customized warehouse layouts can significantly enhance your warehouse management system (WMS), leading to improved efficiency and productivity.Influence of Custom Warehouse Layout on Operational Efficiency

A well-thought-out warehouse layout directly impacts operational efficiency. By organizing storage effectively and reducing travel time during picking and packing, businesses can streamline their processes, ensuring that products are shipped quickly and accurately.How to Design a Custom Warehouse Layout

Designing a custom warehouse layout requires thoughtful planning and the integration of modern technologies. Follow these actionable tips:- Assess your current workflow and storage needs

- Consider using vertical storage options to maximize space

- Implement a layout that facilitates easy access to popular items

- Utilize warehouse automation tools to streamline processes

- Incorporate advanced inventory tracking systems for real-time management

For more insights, explore how to enhance your inventory management system and methods to streamline picking and packing operations. In summary: A customized warehouse design and layout can transform your operations by increasing efficiency and improving order fulfillment accuracy. Next, lets dive into advancements in inventory tracking, ensuring you stay ahead in competitive markets.Streamlining the Picking and Packing Process

Struggling with inefficiencies in your picking and packing processes? You’re not alone.Many businesses face significant challenges with inventory allocation, inaccuracies in order fulfillment, and time-consuming fulfillment operations, especially during seasonal fluctuations.

Zone Picking and Wave Picking Explained

Improvements in Picking and Packing by using a WMS

Integrating a Warehouse Management System (WMS) significantly enhances storage efficiency and order fulfillment accuracy. Key benefits include:A Step-by-Step Guide to Streamlining Picking and Packing Operations

Heres how to streamline your picking and packing processes:- Establish clear workflows to optimize task management.

- Implement barcode technology to improve order accuracy.

- Evaluate and update your inventory management system for seasonal fluctuations.

In summary: By focusing on these strategies, you can effectively address inventory allocation challenges and improve overall warehouse performance. Next, we’ll explore the importance of customized warehouse design to further enhance your operations.Automating the Shipping Process for Better Efficiency

Are you battling inefficiencies in your shipping operations? Youre not alone.Many businesses face challenges like inventory allocation issues, inaccuracies in order fulfillment, and time-consuming picking and packing processes that affect their overall efficiency.

The Role of Automation in Shipping

Automation plays a crucial role in streamlining the shipping process, enabling businesses to address common pain points such as:

Impact of Smooth Shipping Process on Customer Satisfaction

A well-automated shipping process fosters a positive customer experience, leading to higher satisfaction rates and repeat business. Key benefits include:

Automation Strategies for a Smooth Shipping Process

To effectively automate your shipping process, consider these actionable strategies:

For more detailed insights on enhancing your shipping strategy, explore our sections on importance of customized warehouse design, advancements in inventory tracking, and methods to streamline picking and packing.

In summary: Implementing automation in your shipping process not only alleviates common business challenges but also enhances customer satisfaction. Next, let’s dive into the critical strategies for optimizing your warehouse design for even better efficiency.Dealing with Challenges in Warehouse Management

Facing challenges in warehouse management? You’re certainly not alone.Many businesses struggle with inventory allocation challenges, inefficiencies in storage, and inaccuracies in order fulfillment, which can hinder their operations and profitability.

Addressing Pain Points: From Storage Inefficiencies to Order Fulfillment Accuracy

Poor storage efficiency can lead to wasted space and increased costs. To tackle this, consider the following actionable tips:Using WMS to Handle Seasonal Inventory Fluctuations

The ebb and flow of seasonal demand can be daunting. Here’s how to manage it effectively:How to Improve Warehouse Task Optimization and Automation

Optimizing warehouse tasks can greatly enhance operational efficiency and accuracy. Here’s what you can do:- Implement automated picking systems to speed up order fulfillment.

- Train staff on the best practices for using warehouse technology efficiently.

- Regularly review your processes and adapt to any emerging technologies that could streamline operations.

In summary: Tackling challenges in warehouse management is essential to maintaining efficiency and accuracy in your operations. Next, we will explore the importance of customized warehouse design and share methods to streamline picking and packing, as well as automating the shipping process to further enhance your warehouse efficiency.Predicting the Future of WMS

Facing challenges with inventory allocation and order fulfillment? Youre not alone.Inefficiencies in storage, stressful shipping operations, and inaccuracies in order fulfillment can be barriers to achieving streamlined warehouse management.

Current Trends and Future Expectations

The future of Warehouse Management Systems (WMS) is evolving rapidly, influenced by technology advancements and shifting market needs. Key trends shaping the landscape include:Preparing for the Future with Advanced Warehouse Management

To stay competitive, businesses must embrace advanced strategies for their warehouse management. Here are some actionable tips to consider:Moving Forward

To further enhance your warehouse management system, explore the importance of customized warehouse design, advancements in inventory tracking, and methods to streamline picking and packing. Additionally, automating the shipping process is crucial for maintaining efficiency and accuracy. In summary: As you prepare for the future of WMS, integrating these advanced strategies will position your business for success. Next, we’ll dive deeper into innovative automation technologies and their impact on warehouse operations.Frequently Asked Questions

Are you struggling with inventory allocation challenges and inefficiencies in storage? You’re not alone.Many businesses grapple with the complexities of handling seasonal inventory fluctuations, inaccuracies in order fulfillment, and time-consuming picking and packing processes that can bog down operations.

Frequently Asked Questions about Warehouse Management Systems

What is a Warehouse Management System (WMS)?

A Warehouse Management System (WMS) is a software solution that helps businesses manage and optimize warehouse operations, from inventory management to order fulfillment. It provides real-time visibility into stock levels, automates tasks, and improves the accuracy of picking and shipping.

How can a WMS improve inventory allocation?

With a robust warehouse management system, companies can:

What are the benefits of warehouse automation?

Warehouse automation enhances storage efficiency and streamlines operations. Key benefits include:

How does a WMS handle seasonal inventory fluctuations?

A WMS helps manage seasonal fluctuations by:

What is the importance of order fulfillment accuracy?

Order fulfillment accuracy is crucial for customer satisfaction. A WMS enhances accuracy by:

How can businesses streamline picking and packing processes?

Streamlining picking and packing is essential for efficiency. Consider these strategies:

What are the key features to look for in a WMS?

When selecting a Warehouse Management System, prioritize these features:

- Inventory tracking and reporting

- Automation capabilities for repetitive tasks

- Integration with existing systems (like ERP and eCommerce)

In summary: Utilizing a WMS can significantly increase storage efficiency and streamline operations, addressing major business pain points. Furthermore, understanding the importance of customized warehouse design, advancements in inventory tracking, methods to streamline picking and packing, and automating the shipping process will propel your warehouse operations forward. Let’s dive deeper into these critical topics in the next section!FAQ Section: Troubleshooting and Pro Tips

Further Reading

By now, you understand the significant benefits of integrating a Warehouse Management System (WMS) into your operations. Streamlining processes not only enhances storage efficiency but also elevates order fulfillment accuracy, enabling your team to work smarter and more effectively. Don’t let inventory challenges hinder your success; instead, take the next step in revolutionizing your logistics today. Let’s discuss how we can implement this solution tailored to your unique business needs. I encourage you to reach out to David, our CEO via WhatsApp, or email our dedicated Ecommerce Project Consultant at [email protected]. For a personalized consultation, feel free to request a quotation. Join us in transforming your warehouse operations for lasting efficiency!

David Nguyen

Founder & CEO, Cmsmart Ecommerce (a division of Netbase JSC)

With over 20 years of experience in business strategy and ecommerce technology, David Nguyen has empowered hundreds of online retailers around the world to scale smarter and faster. As the visionary behind Cmsmart, he has driven the development of personalization solutions and product-customization tools that deepen customer engagement and boost average order values. His commitment to creativity, practical strategy and results-driven outcomes has earned Cmsmart a reputation as a trusted partner for small, medium and enterprise-level ecommerce brands.

Contact Me via WhatsApp: https://wa.me/84937869689

Email: [email protected]

Let’s talk about how your ecommerce store can grow.

If you're ready to transform your store with tailored solutions that drive engagement and revenue, send me a message on WhatsApp or email today — and our team will connect with you right away.